Design Scorecard Tutorial

Tutorial

When to use this tool

The Design Score is a way to manage the development of a design by tracking the predicted capability of a design to meet CTQs and comparing it to the target or desired capability. Process designs usually use a single scorecard covering the entire process while product designs should be created at the component, sub-system, system, assembly process, and overall level.

Design Scorecards can be used throughout the entire design process but should be started no later than right after concept selection. They can be used to answer the following questions:

- What is the predicted capability of this design?

- What parts of the design exhibit capability shortfall?

- What progress has been made toward achieving the desired quality objectives?

How to use this tool in EngineRoom

You can find the Design Scorecard in the Analyze menu.

1. Select Design Scorecard from the Measure (DMAIC) menu or the Quality Tools (Standard) menu

2. Launch a new Design Scorecard which will open in a new tab

3. Rename your Design Scorecard and press "Create.

4. Fill out what type of process this is:

- Overall: When designing a product, this indicates that this Design Scorecard is for the overall product.

- System, Subsystem, or Component: When designing a product, this indicates that this Design Scorecard refers to smaller and smaller pieces of the overall product.

- Process: When designing a process, this indicates that this Design Scorecard is for the overall process. A process usually has one Design Scorecard

5. Fill out the date

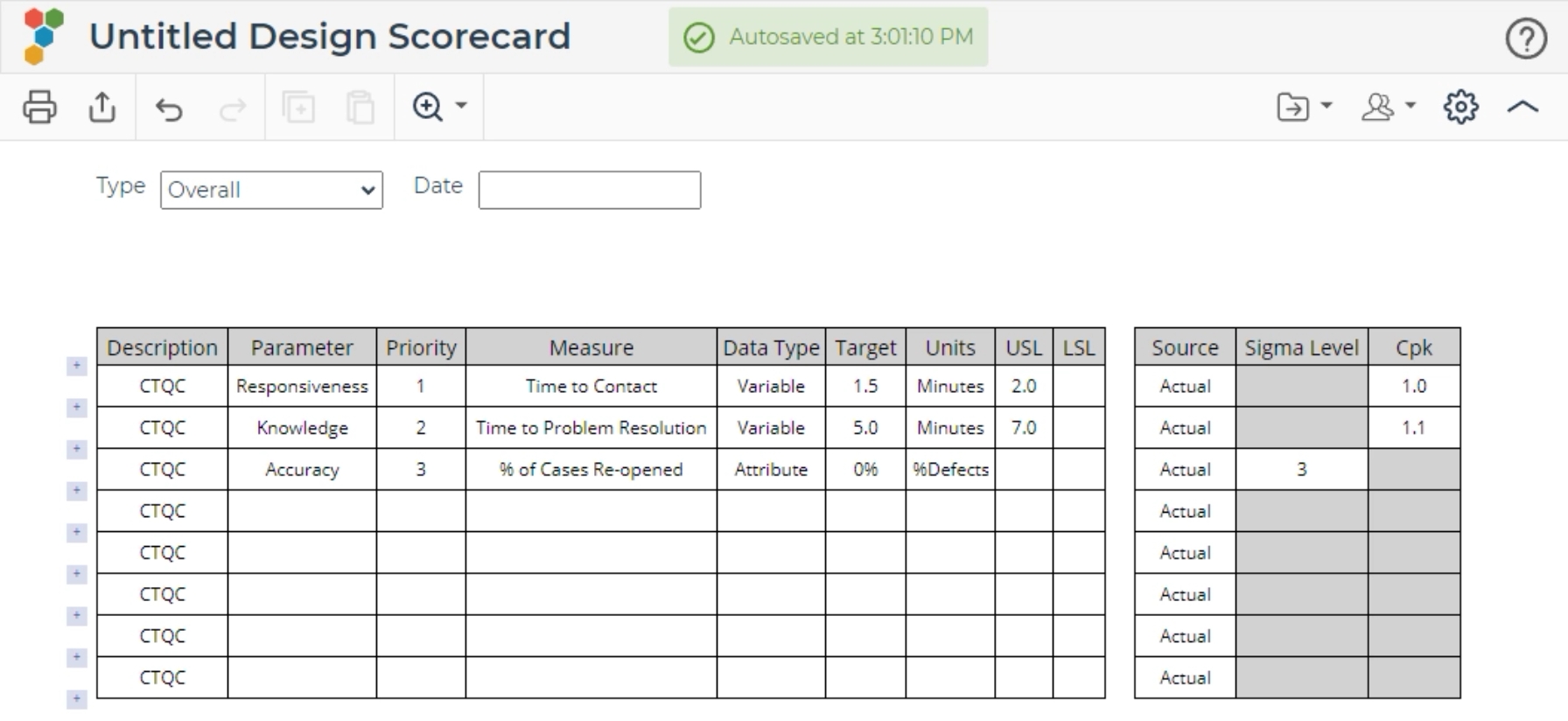

6. Fill out a Parameter (second column). The parameters are the design characteristics you would like your process or product to be measured on

7. In the description dropdown, select what type of parameter this indicates:

- CTQC: This parameter was specified by the customer.

- Dimension: This parameter is a physical characteristic that needs to be met.

- Output: This parameter is an overall result.

- Performance: This parameter is an ongoing statistic of a process characteric

8. Continue filling out the rest of the text boxes to a sufficient level.

Note: The Data Type is either Attribute or Variable. This changes the characteristic needed in the last two columns, either the Sigma Level for Attribute Data or CpK for Variable Data

9. On the right side is a section to record the values to track. The Source column has options:

- Actual: The recorded value is the actual result from the process.

- Benchmark: The recorded value is the result from a similar or competitor process.

- Pilot: The recorded value comes from a pilot of the process.

- Simulation: The recorded value comes from a simulation of the process, not a real-life run.

- Surrogate: The recorded value is a related similar process that represents the process in question

10. Fill in the relevant DPMO or CpK to complete the Design Scorecard

11. Return to the Design Scorecard at meetings to track the measurements that matter to the process design.

An example of an initial Design Scorecard showing the top 3 prioritized CTQCs is shown below:

Was this helpful?