Core Process Pull Tutorial

Tutorial

When to use this tool

Core Process Pull is a simple Kanban-style pull system used to create and maintain a cap on work-in-process. With just a few pieces of information about your process, the Core Process Pull worksheet helps you determine the minimum amount of work in process (WIP) your process can have while still maintaining full output. The worksheet also helps you determine an appropriate plan for reducing WIP from current levels to the new, recommended levels. The worksheet can handle up to a ten step process.

How to use this tool in EngineRoom

1. Open the Core Process Pull tool from Improve in the DMAIC menu, or from Lean Tools in the Standard Menu. Click the ‘Launch’ button to open the template in a new window.

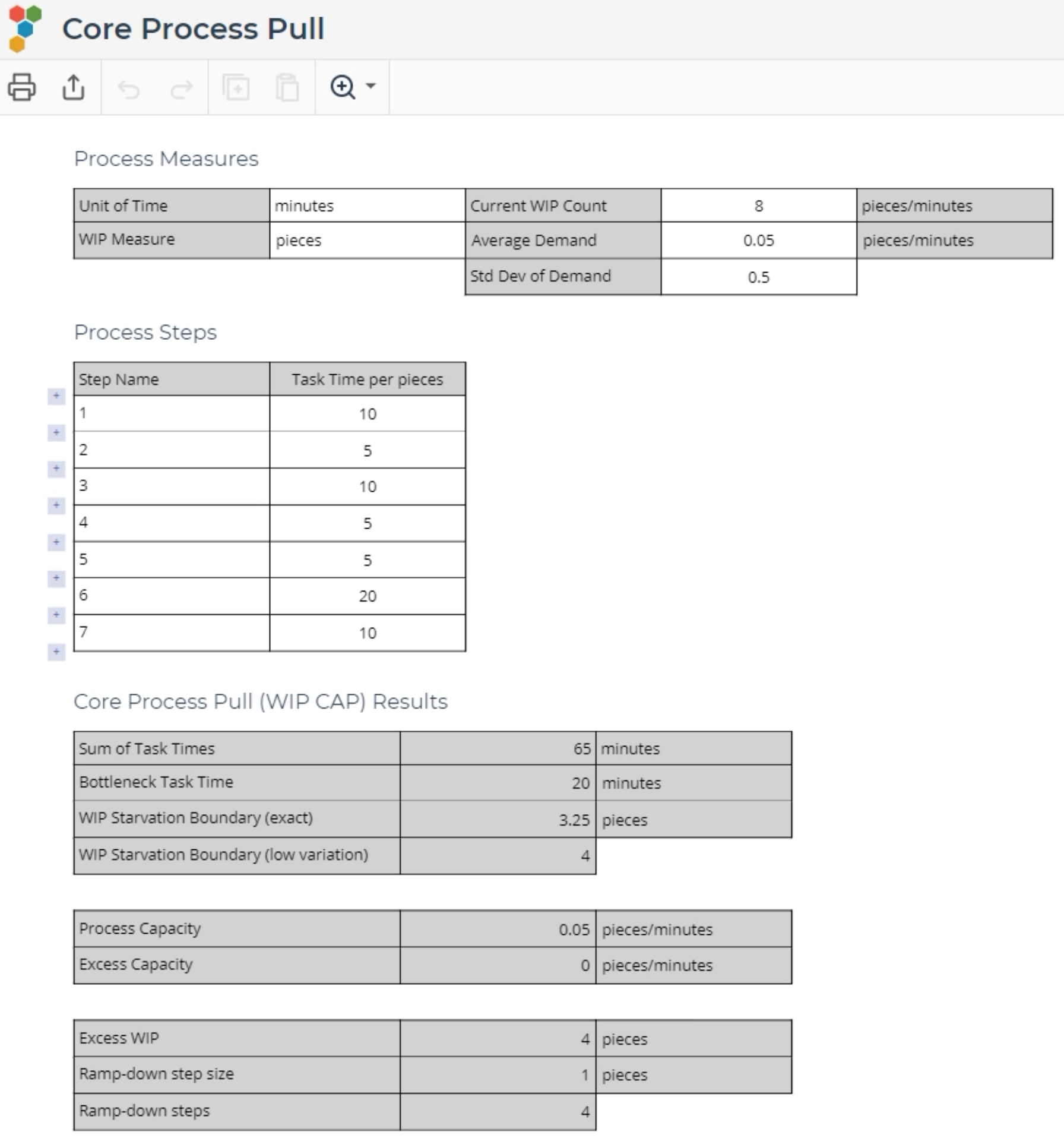

In this example, we have 7 process steps with known task or cycle times, along with information on the demand and current work in process (WIP). Note that these task times should not include any queue time associated with the process step, and are entered based on the Unit of Time you entered.

2. Start by entering the units of measurement of time, the measure of the WIP, current amount of WIP, the average demand and the standard deviation as a measure of the variation of the demand for your overall process.

3. Next, enter the task times for the seven process steps in the Task Time column. You can add or delete process steps using the controls on the left side of each row. The steps do not technically need to be in any particular order.

The Core Process Pull tool produces the following results:

- Sum of Task Times: A simple summation of the tasks times of all process steps

- Bottleneck Task Time: The task time of the longest step in the process

- WIP Starvation Boundary (exact): This is the starvation boundary of the process. If your WIP level drops below this boundary, the bottleneck step will spend some time idle, thus reducing the maximum capacity of the process. This value will be rounded up to nearest integer value to define the WIP Starvation Boundary (low variation)

- WIP Starvation Boundary (low variation): This is the theoretical minimum WIP of the process. This minimum WIP is rarely attainable due to variation the process experiences, both from demand and processing or service time variation

- Process Capacity: This represents the maximum capacity of the process, expressed as a rate, such as pieces per minute. This capacity is based on the slowest step in the process, often referred to as the bottleneck of the process

- Excess Capacity: This represents the spare capacity and is calculated by subtracting the average demand from the process capacity

- Excess WIP: This is the difference between the Current WIP Count you entered and the WIP Starvation * Boundary (low variation) value calculated by the tool

- Ramp-down step size: This value represents a typical starting value for the amount of WIP reduction to target in each step of the Core Process Pull implementation

- Ramp-down steps: This is a simple calculation of the Excess WIP divided by the Ramp-down step size. We don’t bother to round this number to an integer value as you will be adjusting the step size and number of steps throughout the implementation process

The Core Process Pull example is shown below:

During the implementation of a Core Process Pull system, it is important to remember that you should reduce WIP by the Ramp-down step size once, then allow sufficient time for the process to stabilize at the new WIP level. Examine the process for any potential problems that have been exposed by the lower WIP level, such as machine downtime, defects and rework, scrap, long and variable setup times, etc. Once the process is stabilized and it is clear that the bottleneck step(s) are in no danger of being starved for inventory, reduce the WIP by another increment of the step size. Allow the process to stabilize and repeat your inspection for other process problems. Repeat this process as many times as needed until you arrive at your target WIP level. The ultimate target WIP level will often be determined by your customer’s expectation of lead time for the process (see Little’s Law), or your businesses target for working capital investment in WIP in the process. You will not be able to reduce WIP below the starvation boundary without first reducing the task time of your bottleneck steps through continuous improvement work.

Was this helpful?