c Chart Tutorial

When to use this tool

Use the c Chart to monitor the number of defects in subgroups of a fixed (constant) size. This chart allows for multiple defects in each unit (e.g., number of errors in a loan application, number of product returns per [one-unit] day). The number of defects/errors/returns, etc. follow a Poisson distribution.

How to use this tool in EngineRoom

To use the c Chart, collect data on at least 20 subgroups, with the counts of the event in each subgroup listed in a column. You can have an optional time order (date/time or numeric) column variable.

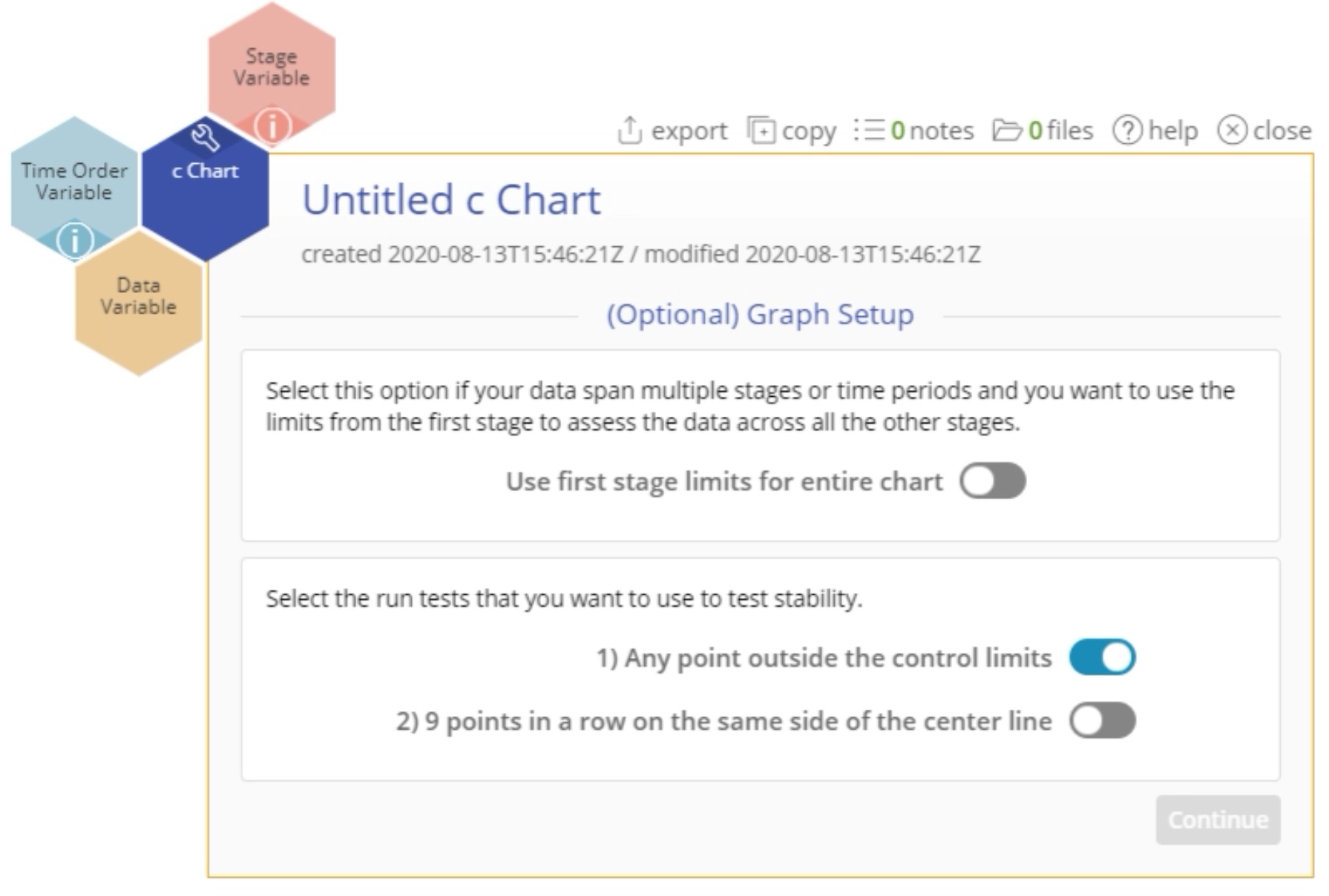

To use the c Chart, select Measure > Control Charts (SPC)... > c Chart. The c Chart study opens on the workspace:

There are three “drop zones” attached to the study:

- Data Variable (required): For the 'number of occurrences' variable. This variable must be numeric.

- Time Order Variable (optional): Use if you have a variable containing the time stamps of the occurrences. This variable can be numeric or date/time.

- Stage Variable (optional): Use if you have a variable identifying different stages (such as “Before” and “After” an improvement initiative). This variable can be numeric, text, or date/time.

Note: The chart demonstration below has the Guided Mode disabled so it combines some steps in one dialog box. You can enable or disable Guided Mode from the User menu on the top right of the EngineRoom workspace.

Example:

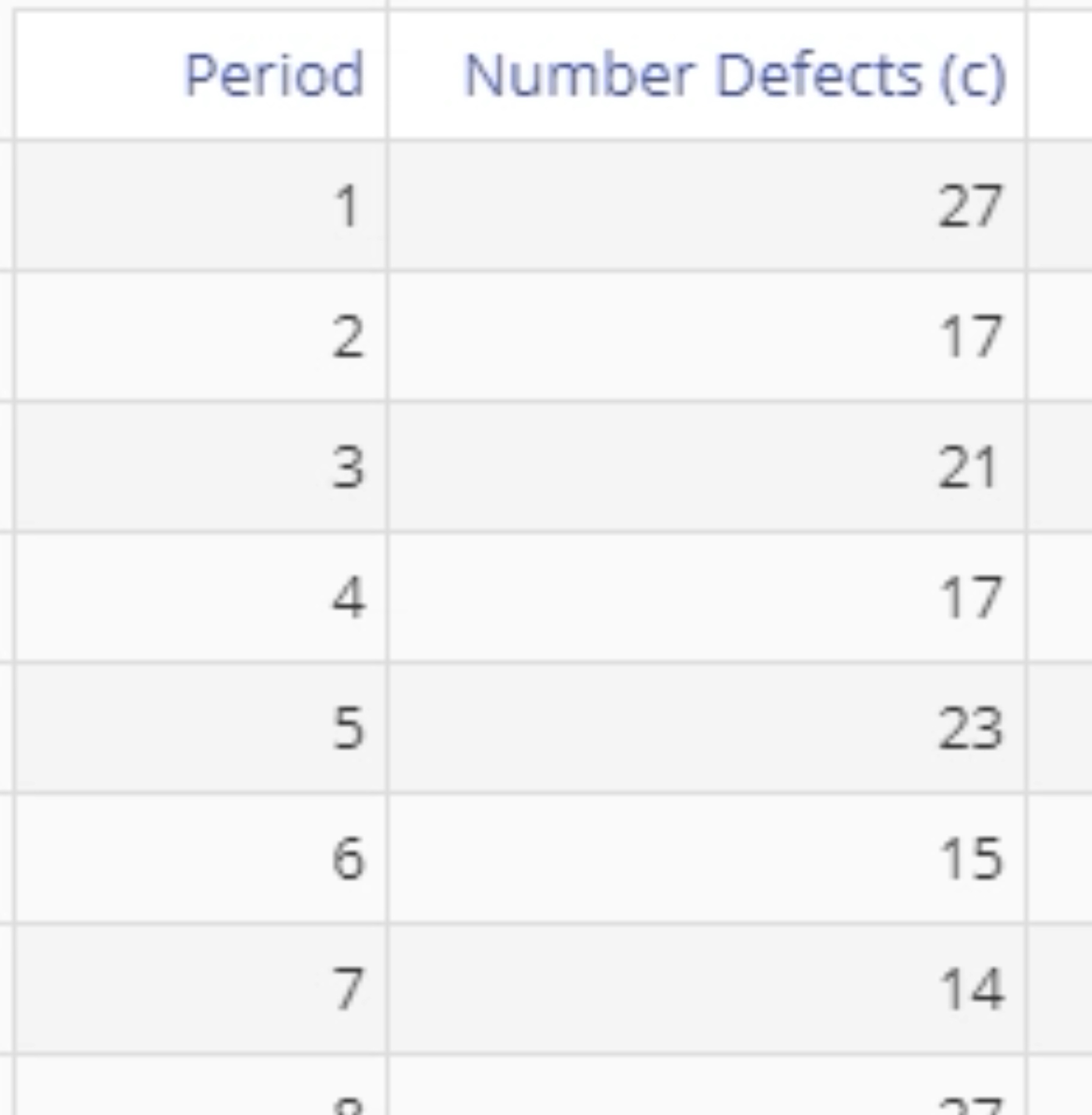

The data set contains a time-order variable (Period) and a data variable (Number Defects) containing the counts of the event in subgroups of constant size:

Steps:

- Open the c Chart tool onto the workspace by going to Measure > Control Charts (SPC)... > c Chart.

- Click on the data file in the data sources panel and drag Number Defects (c) onto the Data Variable drop zone.

- Click and drag Period onto the Time Order Variable drop zone.

- If you have a Stage variable (e.g., “before” and “after” stages or different years identified), drag it onto the Stage Variable drop zone. The control limits are calculated separately for each stage by default, unless you turn on the “Use first stage limits for entire chart” option.

- Select the run tests you want to use. Only the first test (any point outside control limits) is selected by default.

- Click “Continue.”

The c Chart output includes the control chart and a table listing the values of the upper and lower control limits and the average number of defects:

Notes:

- To rename the study, click on the “Untitled c Chart” heading and type in the desired name.

- To edit the chart, click on the plotted points or lines and select the options for thickness, color, and style.

- Select the graph setup button on the top right above the graph to change any of the previously selected settings.

Attribute Control Charts - c Chart Video Tutorial

(c Chart example starts at minute 3:17)

Instructor Resources

Was this helpful?