Control Plan Tutorial

Tutorial

When to use this tool

Process inputs that are determined through experimentation to have a significant impact on CTQ characteristics are commonly referred to as Significant Characteristics or Key Process Inputs. "Significant" means more than just "important", it implies a statistically significant relationship between input (X) and output (Y). Once significant characteristics have been identified, they can be charted, kept in a state of statistical control, and improved by actions to reduce variability.

The Control Plan is the centralized document used to keep track of the status of all significant characteristics. If all of the true significant characteristics are identified and controlled, then the outputs should be predictable. The Control Plan provides the road map for that effort.

Control Plans are generally created at the plant or operation level rather than on a company-wide basis (and are generally controlled documents for ISO purposes).

How to use this tool in EngineRoom

1. Select the Control Plan template from the Control section of the DMAIC menu or from the Project Closeout section of the Standard menu, or from search.

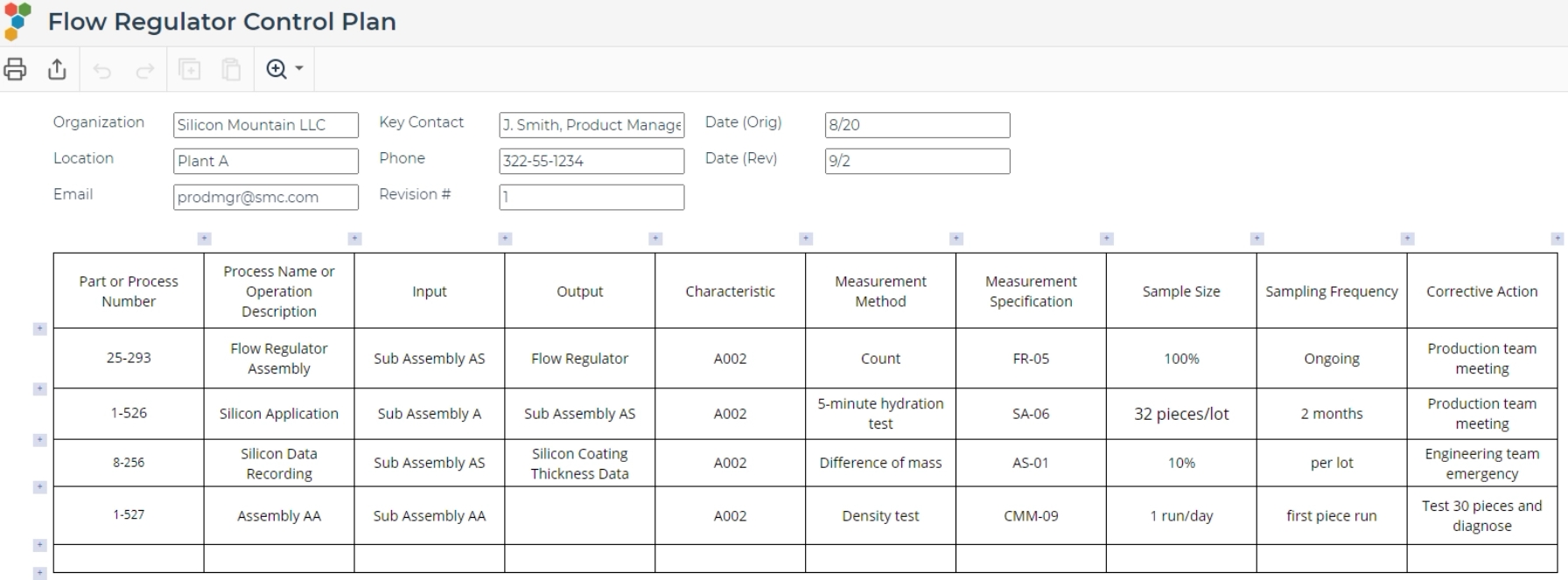

2. Fill in the information at the top of the template, regarding the appropriate contacts and their information.

3. Enter the information for maintaining control, including:

- the part or process number and description

- the inputs and outputs along with the characteristic to be tracked

- the measurement method and specifications

- sampling size and frequency

- any corrective actions to be taken in case the requirements are not met

Note: The Control Plan can be used as a stand-alone template or can be populated from an Input Screening Report.

An example of a Control Plan is shown below:

Was this helpful?