Split Block

The Split Block (or Splitting Block) is used to break an item into its component items. When an item has component items, it is called a compound item. The opposite function from splitting a compound item is constructing a compound item. For more information on that topic, check out the help post on the Kit Block.

The Split Block can be used to represent two different common process scenarios:

Physical Items

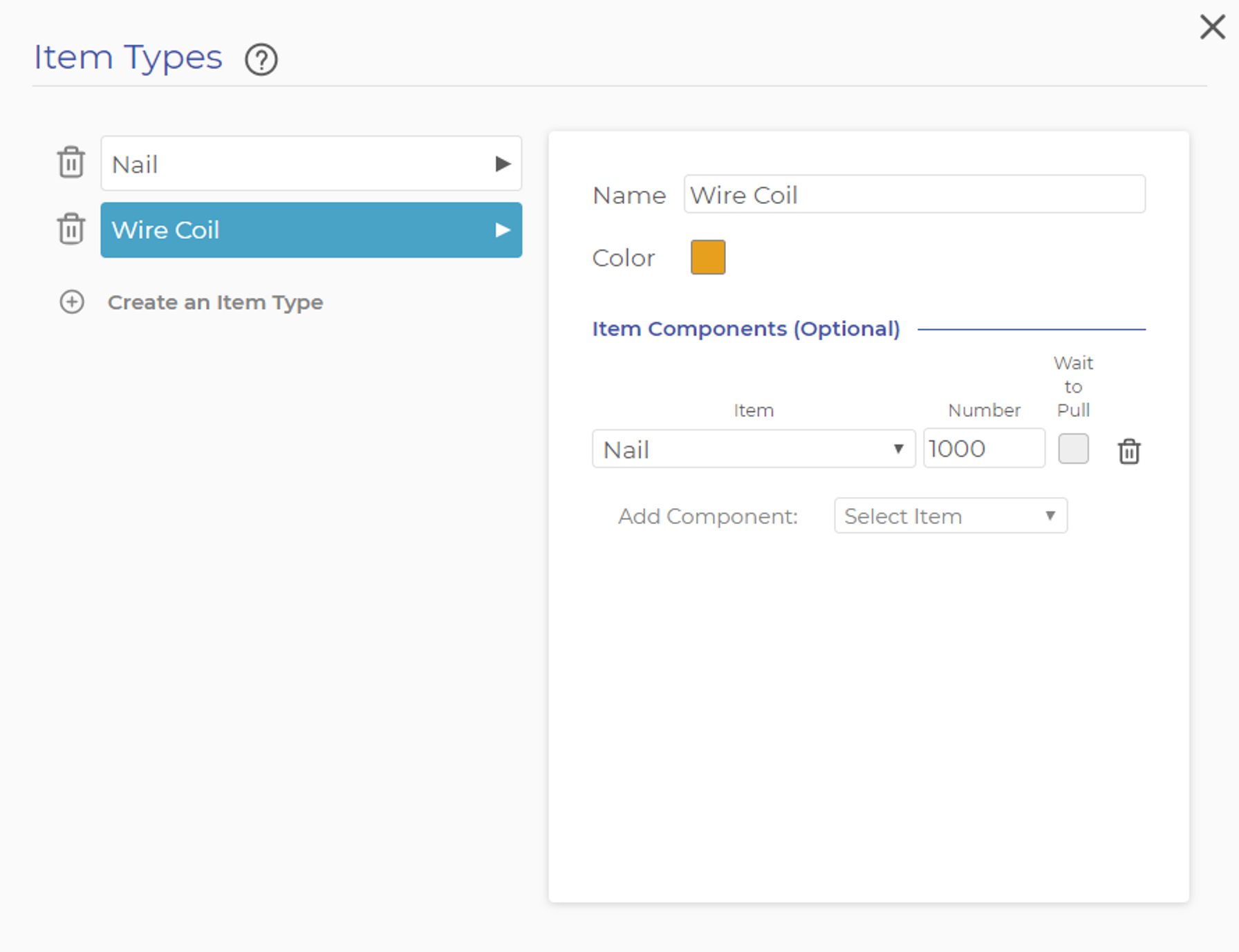

This scenario involves a raw material item that is transformed into many copies of a new item. A typical manufacturing example of this is the production of nails, bolts, or screws. A large coil of wire is loaded into a machine, which then cuts a piece from the roll to form a nail. To accomplish this in Process Playground, you need to create two items: the “Nail” and the “Wire Coil” that can be cut apart to create 1,000 “Nail” items. The image below shows how these two items are constructed in Process Playground.

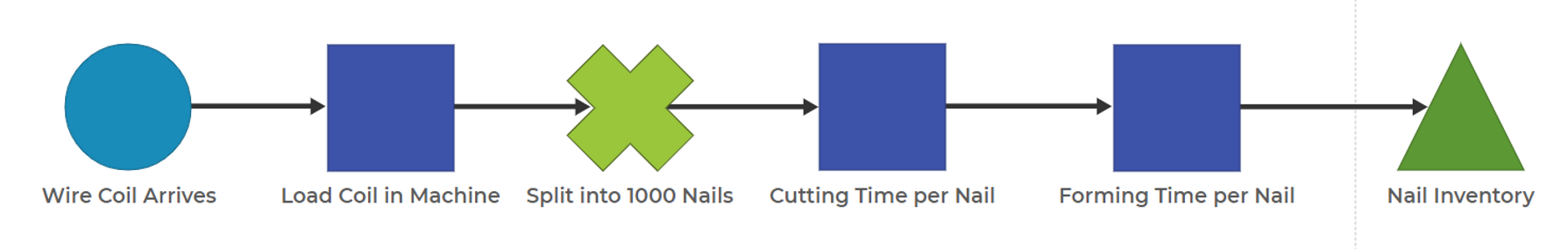

In this example, a single item, the wire coil, was split into 1,000 nails. Note that the Split Block creates the nails but does not consume any time for the operation. As such, you must add one or more Activity Blocks before or after the Split Block to represent the time consumed for the nail-making tasks. A sample of how this process may look is shown below.

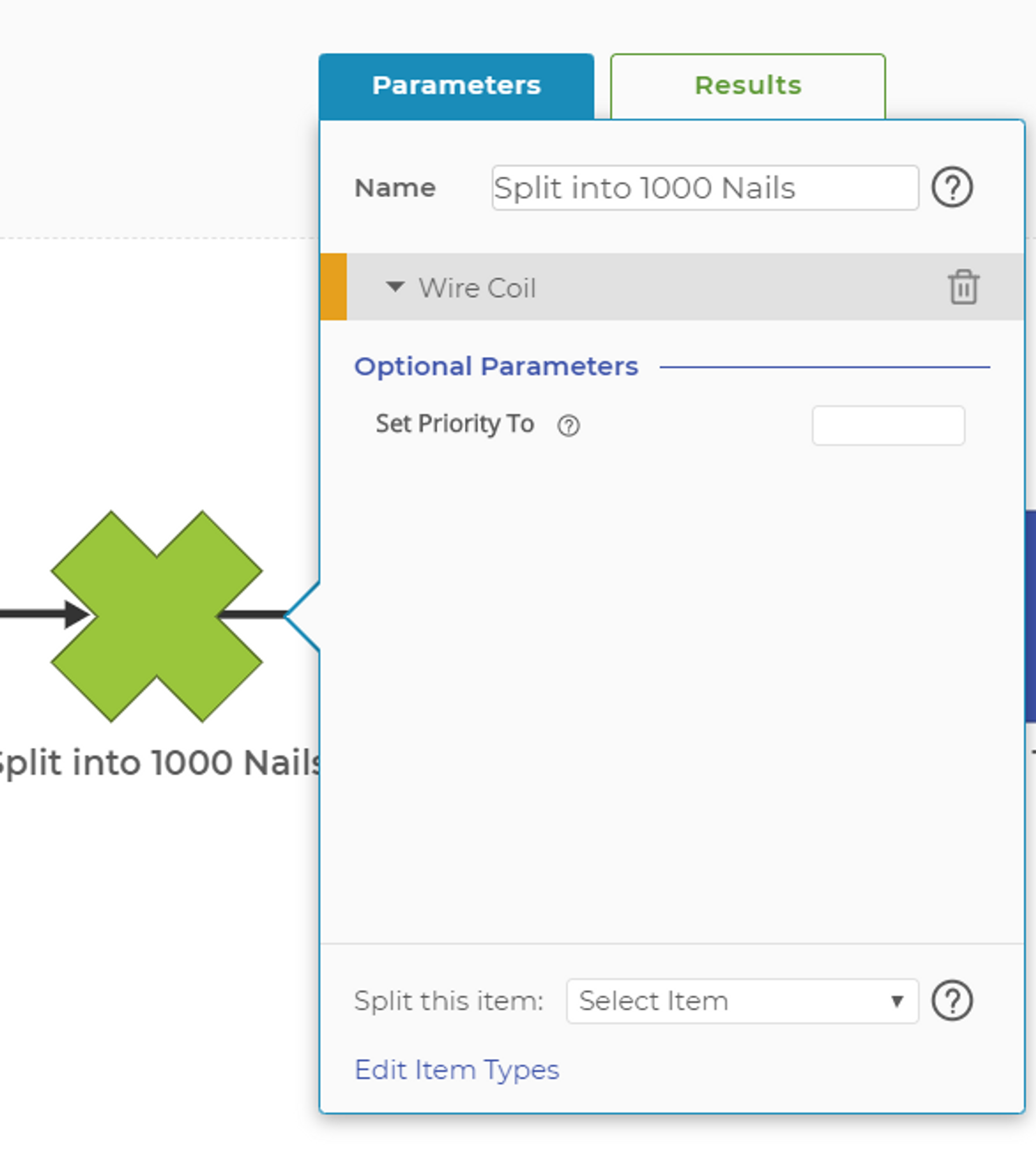

The item type to be split must be selected in the Split Block. As with the Kit, Queue, and Activity Blocks, no items can flow through the process to the block if an item is not selected in the block. (See Managing Flow in Process Playground for more information.) Select the item type at the bottom of the parameters dialog box, where only one parameter setting will be available after adding the item to the block. The "Set Priority To" parameter allows you to change the priority of the resulting item – in this example, the nails - from the default priority of 5. Note that you can add as many compound items to the Split Block as necessary to represent different items being produced in your process. Only compound items are listed in the item list at the bottom of the parameters window.

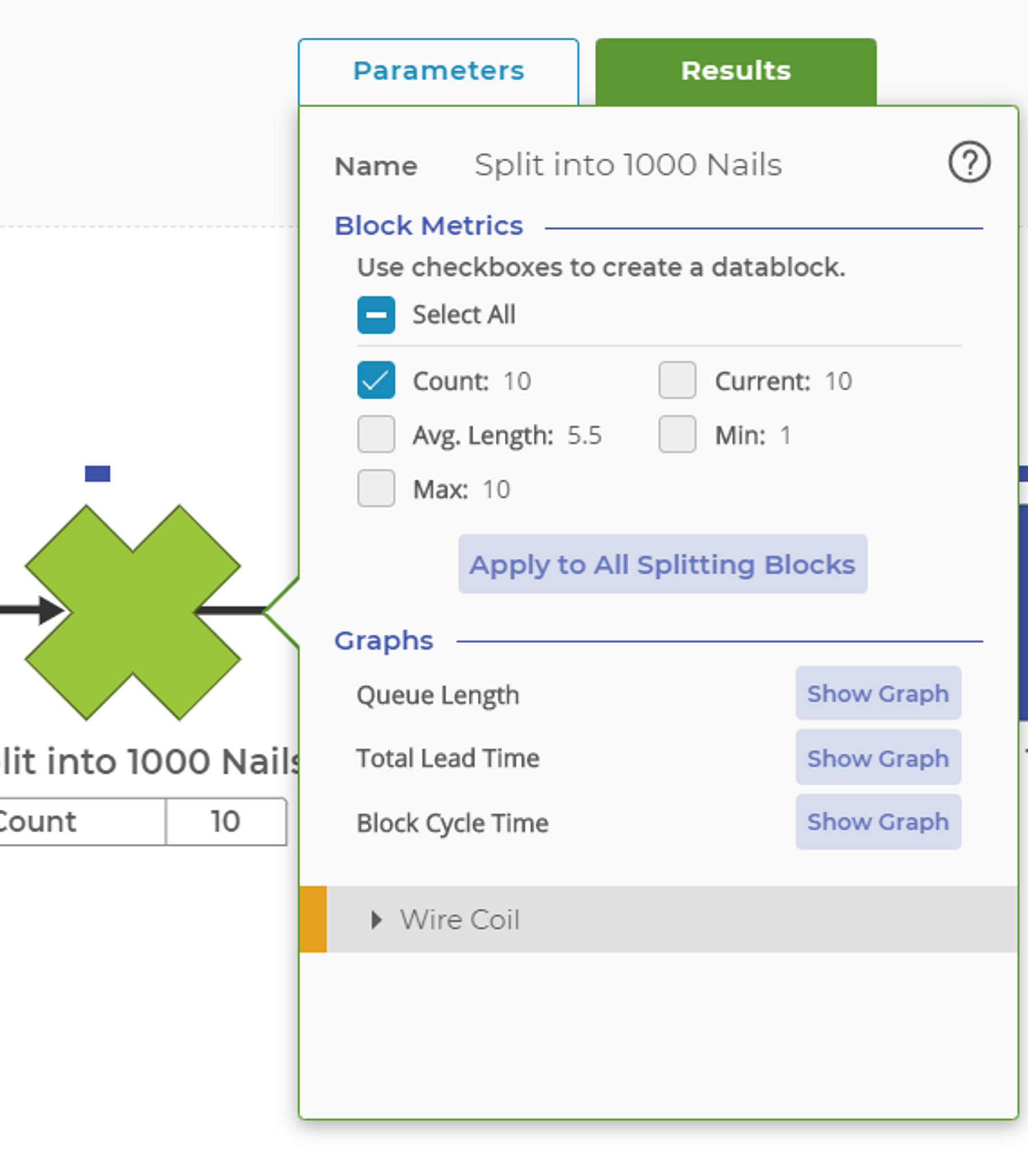

The Split Block returns results in a similar fashion to the Queue Block. Most of these results, however, are not particularly useful as the block is queuing the input item (the wire coil). The most important result is the count, which indicates the number of wire coils the block has processed.

Logical Items

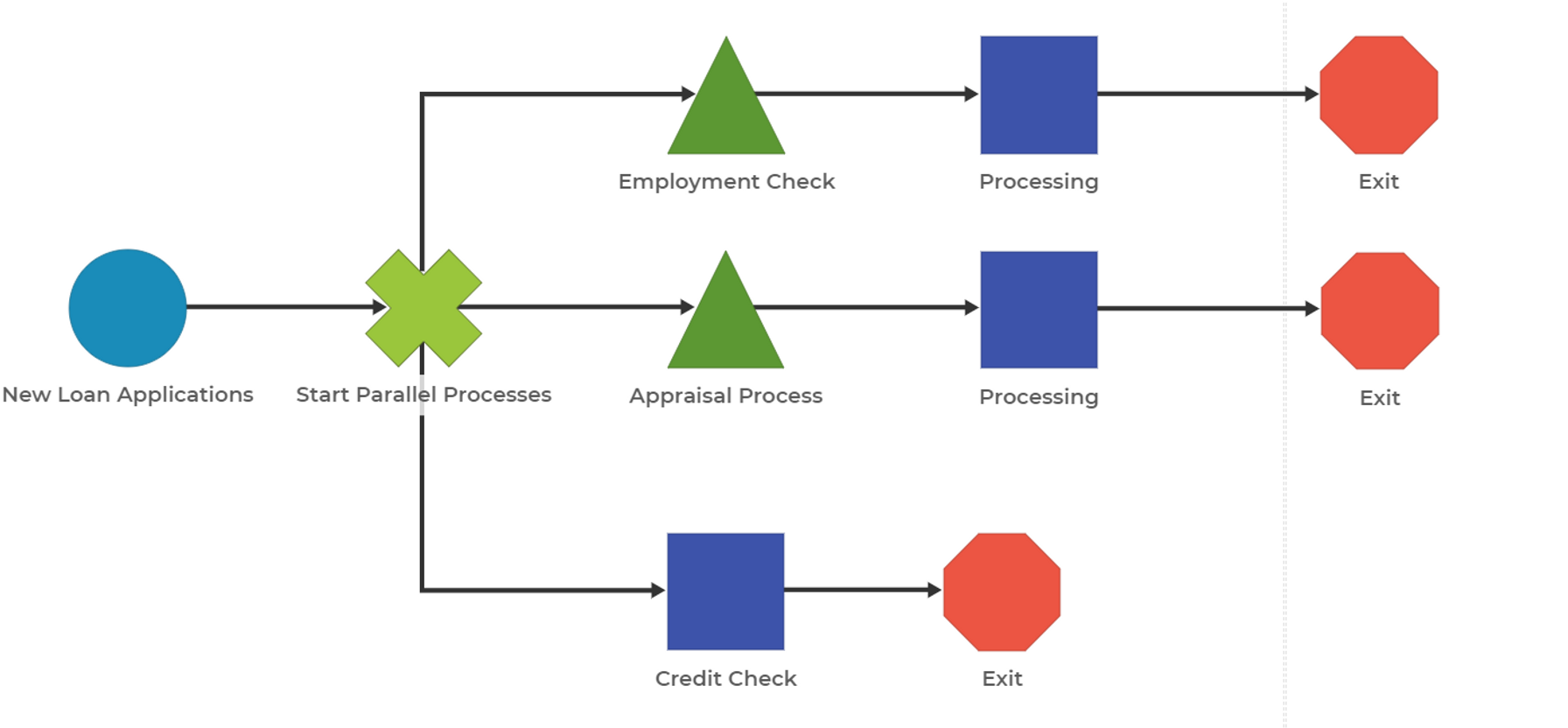

This scenario involves launching several parallel processes in response to a single event. In the example below, the event is the arrival of a loan application. That event then starts three processes: the credit check, the appraisal, and the employment check.

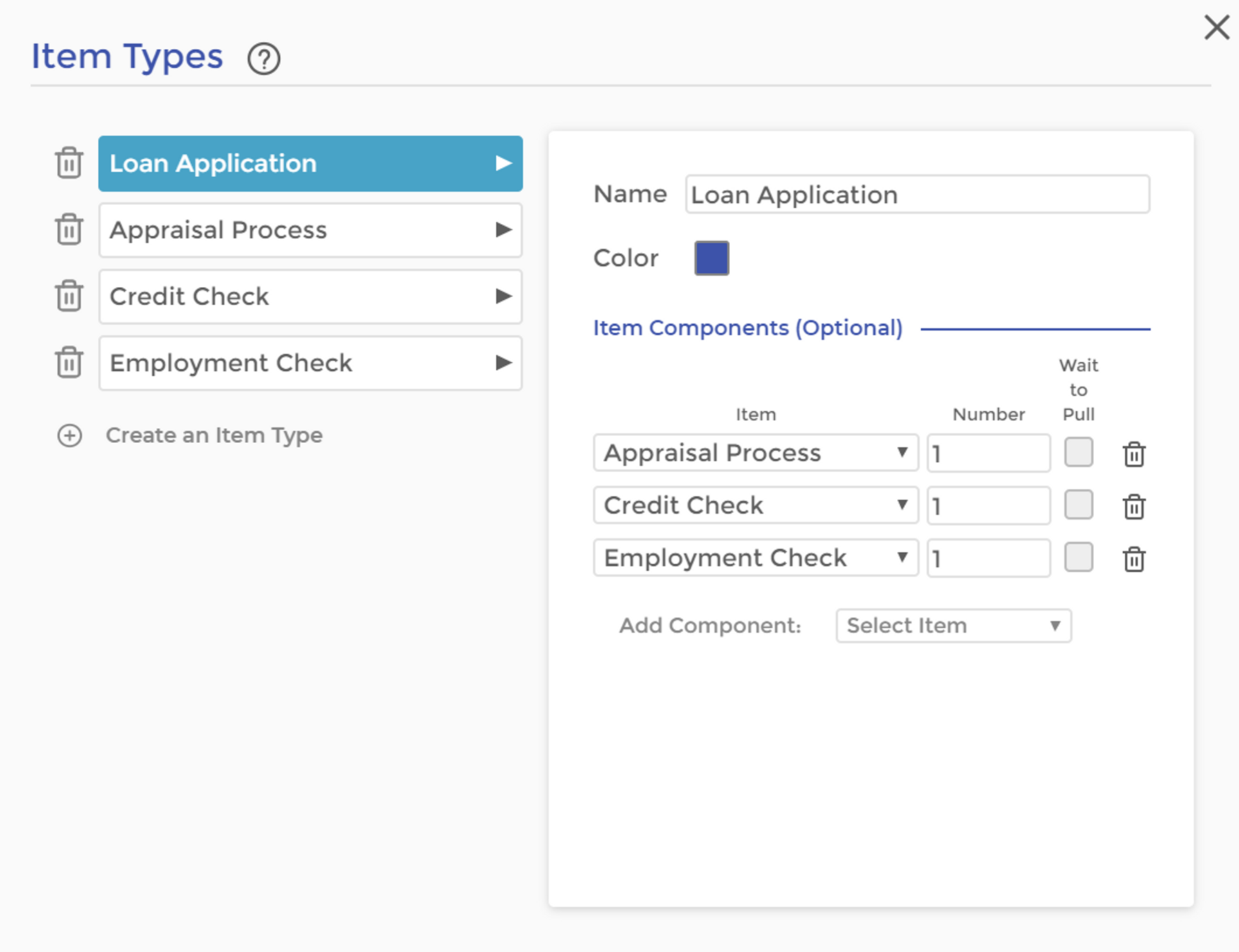

The "Loan Application" item is structured as a compound item, with the other three items as components of the loan application.

In the model, loan application items are generated in the Demand Block, then flow to the Split Block, where they are transformed into the three component items.

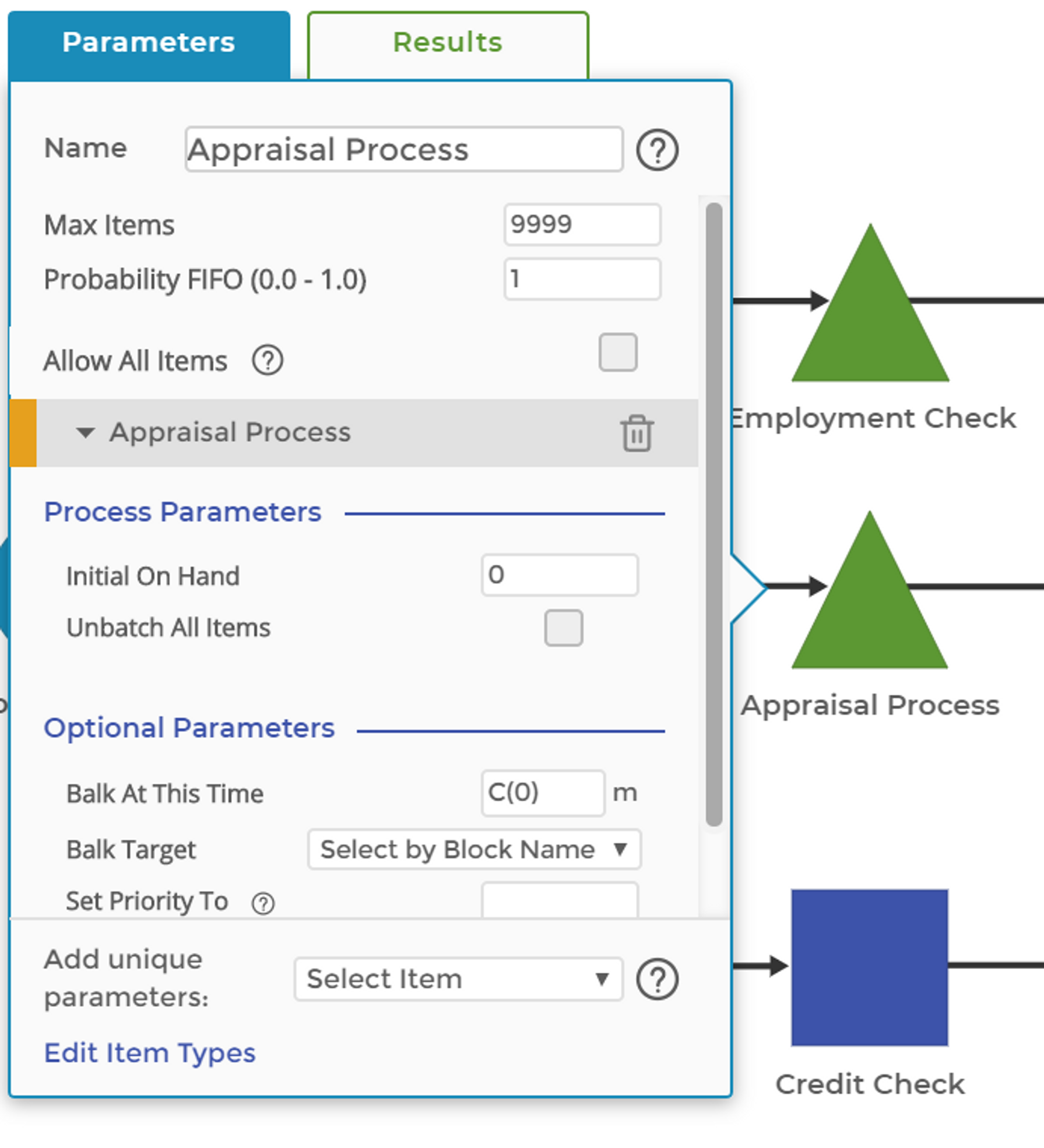

Each of these component items flows to a Queue or Activity Block where the "Allow All Items" functionality has been turned off and the unique item is added to control the flow of the component items to flow into the three sub-processes.

Both logical and physical items can be used together as component items in a parent item. Imagine a car that arrives at a service shop. The physical item would flow into the shop process, while other logical items, such as the billing or warranty claim processes, are started by logical items.

Maintaining Matches at Kit Block

This important flag tells a Split Block that the items that are split should recombine at some point at a Kit Block (which must also have "Maintain Items" checked). For example, in a process where a patient comes into a hospital for the Emergency Room, the "Stat Patient" may be split into "Patient" and "Stat Paperwork," each of which goes through its own process. However, not just any "Stat Paperwork" can be paired with any "Patient"; the two must have come from the same original Stat Patient for the model to be accurate. To accomplish this, make sure both "Maintain Match at Kit" and, in the corresponding Kit Block, "Maintain Items" are checked.

Was this helpful?