Warehouse with Consumable Parts and Reusable Equipment

Warehouse with Consumable Parts and Reusable Equipment. This model incorporates check-in and check-out processes for reusable equipment while looking at the requests for consumable spare parts.

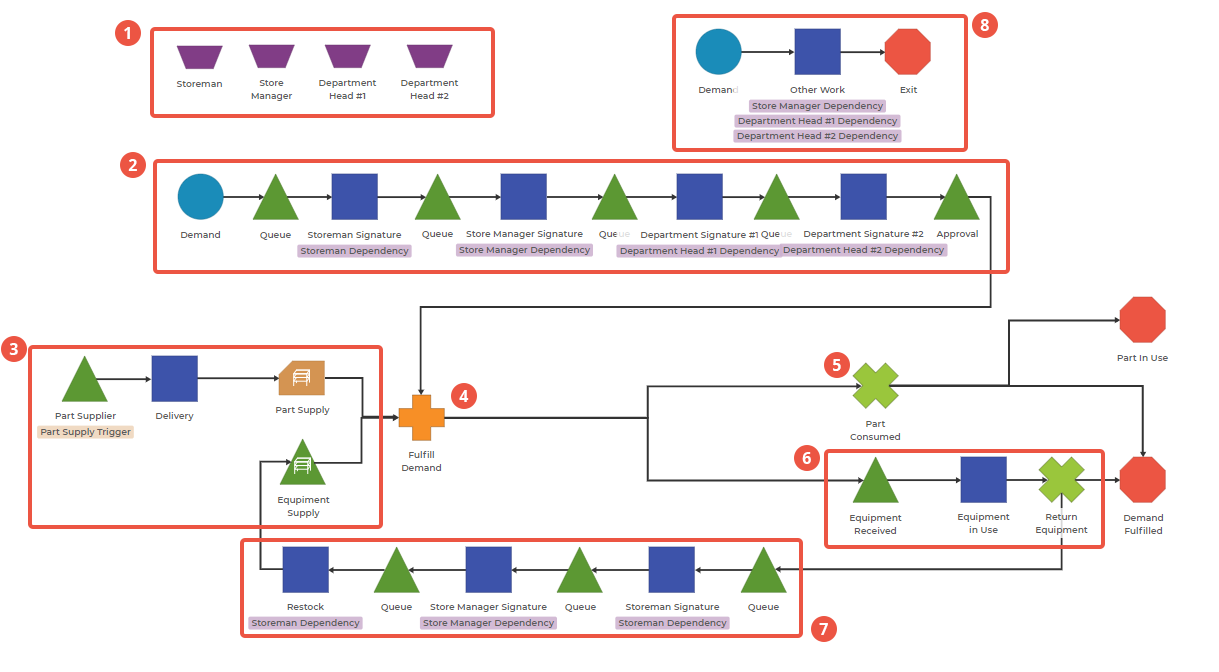

0. This process has seven items: Request for Part, Part, Fulfilled Part, Request for Equipment, Equipment, Fulfilled Equipment, and Other Work.

1. Create Your Resources. In this model, we want to account for the time of an employee across different parts of the process. This measurement is done with Resource Blocks. In this case, we've created one resource block representing each worker. This setup is exactly the same as last week!

2. The Check-Out Process. This top line represents someone requesting a part or a piece of equipment. It starts with a Demand Block that generates Request for Part and Request for Equipment items. Then, these items move through a series of Approval Activities that the respective Resource Block staffs. If the resource is unavailable, the requests will wait in the preceding Queue Block.

3. The Warehouse. The shelf icons denote the Warehouse holding the spare Parts and Equipment. The Parts are held in the Replenishment Pull block (Part Supply), and when they get low, they trigger the ordering process to the Part Supplier. The Equipment is held in the Queue Block (Equipment Supply), which includes the item and has "Initial On Hand" set for the amount of Equipment we have.

4. Combine Requests with Parts/Equipment. This Kit Block creates Fulfilled Part and Fulfilled Equipment items by combining a Part with a Request for Part or an Equipment with a Request for Equipment.

5. Consume a Fulfilled Part. This Split Block only allows Fulfilled Parts. When the Fulfilled Part gets split, the Part gets "used" and is sent to the corresponding Exit Block. The Request for Part goes into the Demand Fulfilled Exit Block. This is just to keep all the Requests together, but you can easily add more or fewer Exit Blocks to this model.

6. Use reusable Equipment. The starting Queue Block in this section only allows Fulfilled Equipment. The Fulfilled Equipment passes through the Activity Block, representing someone using the equipment for a specified period. Then, the Split Block begins the return of the Equipment to the Warehouse while splitting off the initial Request for Equipment.

7. The Check-In Process. An Equipment Item has a process of checking back into the Warehouse involving signatures. It is just like the process for Request for Equipment but leads back to the Warehouse.

8. Establish "Other Work" to accurately reflect time spent on approvals. A vital part of this model is this subprocess for Other Work. Since various employees can't dedicate all their time to one task, the requests will accumulate in the blocks until they can complete them. Assigning time between 30 and 120 minutes per Other Work item simulates that the Resource "makes time" for approvals but primarily focuses on their other tasks.

This model is a slightly different take on our model from last week. We introduce the concept of reusable Equipment and manage both of those item types in different blocks, allowing them to flow through a similar process and then get returned to the main store in the case of Equipment or replenished via an order in the case of Parts.

Was this helpful?