The Great Retirement: The Five Lean Principles That Can Save Your Business

May 5, 2022Amidst the global pandemic, hundreds of Americans retired earlier than expected; choosing an early retirement proved to be more beneficial than returning to work after a long hiatus.

As a result of The Great Retirement, thousands of businesses struggled to hire more workers, even after offering very appealing working conditions.

Lean methods are more important than ever when key inputs like labor are constrained because eliminating waste frees up capacity.

The whole objective of lean methods is to improve the flow of value to customers, but that doesn't mean all possible customers of all potential product offerings. Complexity is sand in the gears of lean methods. It's crucial to decide which customers you want to serve with which products. Applying the five lean principles to your current process improvement model could result in better business and a thriving economy.

In September 2019, I was listening to a presentation at MoreSteam's Best Practices in Operational Excellence conference when a guest in the audience made an interesting comment. He said that in the 1990's he was investing in automation and Lean improvements to lower costs, but in the 2010's he was investing in automation and Lean improvements to gain capacity — not because his business volume was up, but because he could not find people in the skilled trades. For him, automation and waste reduction was forced upon him because of the short supply of skilled labor and the binding constraint that put on his business. I find this ironic. Lean is often maligned as nothing more than another way to reduce headcount, but in this case the labor market chose to self‐reduce by exiting the market entirely.

Remember, this was the fall of 2019. Fast forward six months later, and the Covid‐19 pandemic takes hold. Now, businesses scale back or close completely, unemployment skyrockets, and nothing is certain. Another year later and industries pick back up again. Whatever the cause, whether it be pent-up demand or $5 trillion of stimulus injected into the economy, business was ready to roar. We finally all head out to dinner and run head-on into a familiar problem — the labor shortage is back, and it now extends far beyond the highly skilled machinists that were missing in 2019.

I live in Sarasota, Florida. Because of all the sudden shutdowns, labor shortages, and unemployment rates, a local restaurant owner has to restrict his hours of operation from 9 am to 3 pm. He used to stay open until 10 pm and would like to again. The menu is excellent yet straightforward: sandwiches, salads, and tacos. At $30/hr, he's unable to find a line cook for the kitchen, and he often has to act as cook, host, and server himself. Unfortunately, this scenario is not unique to most organizations; this song and dance is applicable to seemingly every industry across the country. A Florida McDonald's had to resort to paying $50 just for people to show up for an interview!

Combating the Great Resignation Through Lean Thinking

So many vacancies now exist across almost all sectors of the economy. How did we go from struggling for skilled trades to one of the largest unemployment rates in history and back again, yet we still face a labor shortage? Where did all the people go? I'll admit to being curious and confused. How did the labor market capacity drop so significantly due to the pandemic?

Living in Florida, I only needed to go for a walk around town to find that answer. The Great Resignation quickly became The Great Retirement, in the words of Helaine Olen of the Washington Post. Olen talks about how service industries had become more dependent on older workers in the wake of The Great Recession of 2008. She also discusses how the pandemic became the impetus for the baby boomer generation to exit the workforce and retire ahead of schedule. A booming stock market driving 401k balances to new heights (up 466% since 2009 per a CNBC study) certainly helps the retirement math work out.

So, two years later here we are at the heart of the problem. The labor shortage is largely due to the pandemic affecting those closest to retirement, and nudging them to make the leap earlier than expected. But how can businesses adapt and recover to an economy amid The Great Retirement? Perhaps the time has never been better to revisit the five lean principles with a few enhancements.

Just as a reminder, the five lean principles are:

- Identify Customers and Specify Value

- Map the Value Stream

- Create Flow

- Respond to Pull

- Pursue Perfection

Stay connected to the OpEx community by signing up for our newsletter!

Principle One — Identify Customers and Specify Value

The first principle typically talks about identifying current and potential customers and then clearly understanding the needs of those customers to deliver exactly the value those customers require. An embedded assumption has always been the pursuit of more. More customers are getting more value, in more markets, with more profit. The capacity side of the equation is always assumed to be infinite. Given that we build a better mousetrap and deliver the most value, we will always be able to grow and expand.

But what if a critical resource, labor, becomes constrained? Simply maintaining capacity may become a daily struggle, and going back to the example of the restaurant in Sarasota, doing less may be the only option available. So if we're the restaurant in Sarasota, facing an unprecedented constraint on capacity, what are the alternatives to consider? This leads me to my first enhancement of the five principles of lean.

Choose your customers, don't just identify them. The natural instinct, and rightly so, of every sales and marketing person is to capture the attention and pocketbook of every potential customer. This concept is fine in principle but more complex in the details. As production capacity scaled back during the pandemic, we saw a far‐reaching culling of marginal brands. Coca‐Cola cut over 200 brands from its portfolio.

Why? The answer is very Lean. Each brand you carry, or each unique customer segment you're chasing, introduces complexity and variation into your processes. In the case of a bottling plant, the complexity causes product changeovers. A setup is required to clean the bottling equipment, make adjustments for a different bottle style, change the labeling, etc. Multiply that effort further to all of the management and marketing of the brand and the complexity becomes overwhelming. You could spend a lot of time and effort trying to improve those changeovers, or you could eliminate the need for changeovers entirely by paring back the product offering.

From the smallest restaurant with just a few people on staff to the largest conglomerates, businesses accept increased complexity as a given in the pursuit of every possible customer. The result is rampant setups, batch operations, excess material handling, and investment, both in fixed and working capital.

Given that the world has handed us a new constraint, now is the time to question our product and service complexity, intentionally choose our customers, and focus our newly limited resources on excelling at delivering value to our selected customers. Choosing your customers is the foundation of strategic thinking in Lean, balancing your capabilities and capacity against what the market demands.

Principle Two — Map the Value Stream

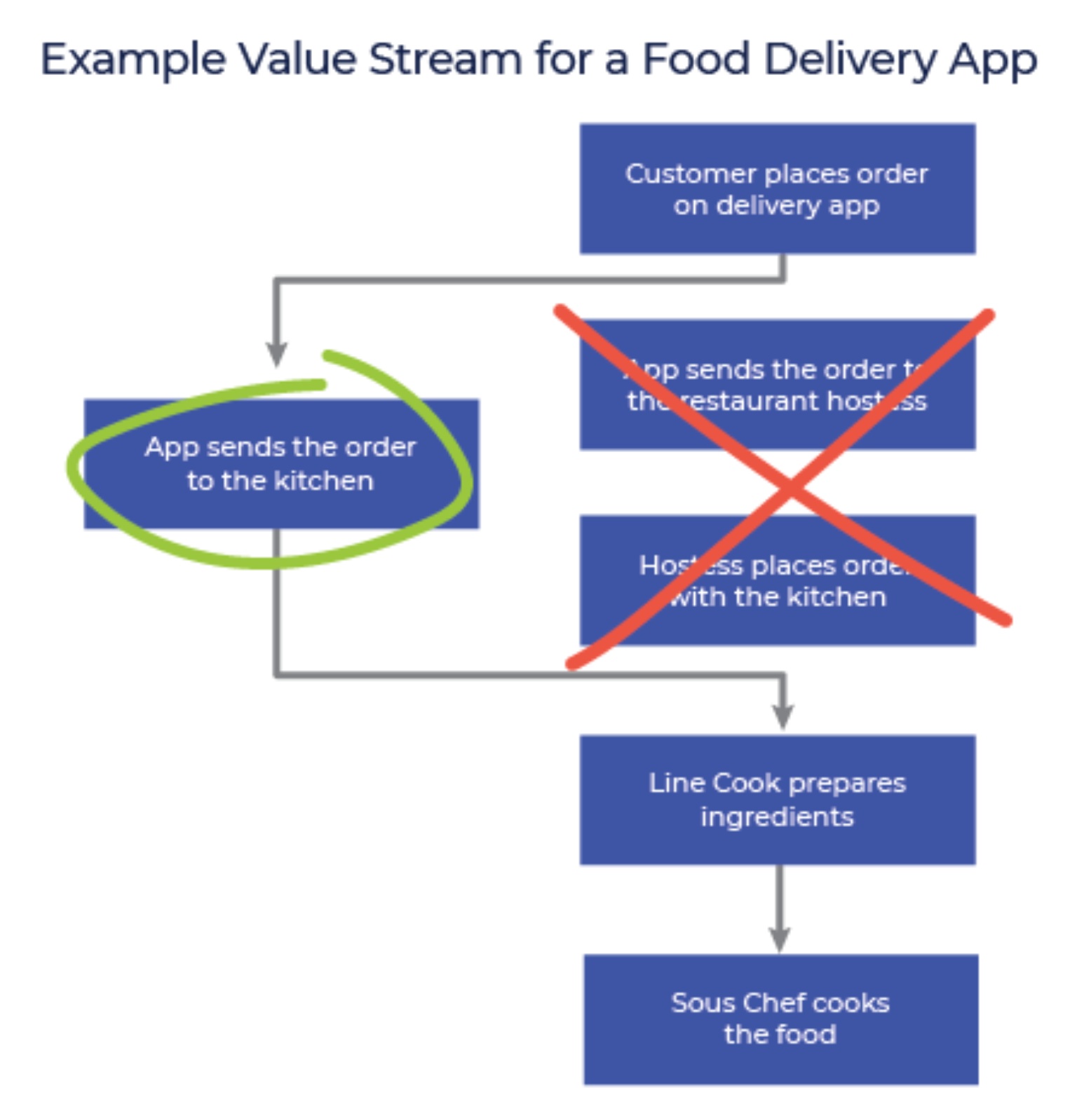

At the beginning of the pandemic, several clients reached out to me asking for assistance in responding to the challenge that physical distancing requirements placed on their processes. Value stream mapping is designed to focus your thinking on the customer, and the process, or value stream, that the customer experiences. The primary "value" to the customer became safety from a life‐threatening disease. Needless to say, the focus on the customer experience was never sharper.

We started by mapping the existing processes (always map your processes, every one, every time) but then we had to figure out how to adapt those processes quickly, in real‐time, while minimizing the risk from a new threat that we didn't yet understand. This leads me to my second enhancement of the Lean principles.

Design your value stream, don't just map it. Lean thinking is by design and its language, built around the idea of continuous improvement. Inherent in the words "continuous improvement" is the idea that we will iterate from our current process (hopefully in a rapid fashion), continuously changing and improving. But we are always starting from our current process, and that can limit us when we face unprecedented changes in our operating environment. In executing our pandemic projects, we had to figure out how to design processes that were more than a few changes away from current processes or even entirely new.

For this, we turned to process modeling and, more specifically, discrete event simulation (DES) using Process Playground. Discrete event simulation allowed us to take the data from the existing process maps and use that to design and simulate the new or revised processes. Note: there is a risk of extrapolation error as we deviate further from the current operations.

The modeling exercises allowed us to virtually pilot the new processes repeatedly and fine‐tune the process parameters before we implemented the strategies in what became simultaneous pilot/go‐live events.

The process modeling also allowed us to anticipate how the process would react if we were wrong in our assumptions or if conditions changed, allowing us to think about and plan for contingencies. We built our FMEA (Failure Mode and Effect Analysis) based on the process modeling to know how to adapt as the new process interfaced with reality. Process modeling has additional benefits as we look at the following two Lean principles.

First time modeling a process map? Learn how by checking out this webcast.

Principles Three and Four — Create Flow and Respond to Pull

Most Lean methods and tools are deployed under the broad topics of creating flow and responding to pull. Recall DOWNTIME and the eight wastes we attack in Lean:

- Defects

- Overproduction

- Waiting

- Non‐utilized Resources

- Transportation

- Inventory

- Motion

- Excess Processing

When facing any severely constrained resource, elimination of waste is critical. In a tight labor environment, it becomes even more critical to tap into the full capability of every human, (the 'N' in DOWNTIME). Minimizing the other seven wastes helps ensure that no talents, skills, or abilities are squandered.

Turning back to the restaurant example: excess motion in the kitchen wastes the staff's time. Perhaps adding extra garnishes to a sandwich plate is an example of over‐processing waste? The cost of the garnish itself may be trivial, but the ordering, receiving, cleaning, storing, preparing, and presenting of the garnish all consume valuable labor. Keeping the eight wastes front and center in our minds is key to allowing the best use of our limited labor capacity to create the most value for our customers.

Taking from the discussion of Principle One, choose your customers; creating flow in a process is more achievable as the process's complexity reduces. Think about the wastes produced by complexity. Excess inventory, as we attempt to forecast demand across a more complex product offering. Defects, as fewer people try to switch between various service offerings. And waiting, as both employees and customers wait for a complexity‐induced imbalance to work its way through our process. We rarely understand the impact of complexity on our operations, and we are programmed to pursue every penny, even if it costs us a dime to get the penny.

Back to process modeling, discrete event simulation can help us understand the impact of complexity on a process. What are the failure modes and effects of introducing soup to our sandwich and salad menu? Will the soup truly drive additional business or avoid the loss of business, or will it just cannibalize sales of sandwiches? Or, will the addition of soup significantly disrupt and imbalance our process so that our service time rises and we lose all of our customers?

Stay‐up‐to‐date on all things Moresteam by following us on LinkedIn!

Principle Five — Pursue Perfection

"Jack of all trades, master of none…"

Pursuing perfection is the final Lean principle and speaks to the heart of Lean, continuous improvement and the relentless elimination of waste. Of course, the remainder of the saying above is "...but oftentimes better than a master of one". And so the problem is that we can neither afford to do just one thing perfectly nor can we attempt to do all things just okay.

Lean focuses on finding the right balance between our process design and our product and service offerings. The past two years have forced us to deal with supply interruptions on an unprecedented scale. While the supply of materials and equipment is slowly working itself out, the collection of talented people is a step‐change in our society that will not work itself out. The Great Resignation is indeed The Great Retirement. We will all have to figure out how to choose our customers wisely, focus on creating exactly the value they need and use every Lean toolkit to ensure we don't waste a single minute of time.

The Bottom Line

So what is the restaurateur in Sarasota to do to combat the great retirement? He has fixed costs, most significantly rent, that are skyrocketing. Because of labor constraints, he's unable to stay open as long as desired and, therefore, unable to maximize the return on his monthly investment in rent and other fixed costs. His opportunity cost now comes into focus — are the net returns from the restaurant higher or lower than what he could earn from applying his labor somewhere else? Or, can he improve his processes sufficiently to either lower costs or improve capacity to the point where he can stay open longer?

We know for sure that he is multitasking like never before. Whenever we lack the people we need to fill available jobs, those who remain on the job inevitably have to wear many hats.

Decisions drive the journey to becoming Lean, and some of the most important decisions involve identifying what not to do. By selectively doing less, you can free up the capacity to do more.

In my next blog, we'll talk about the impact multitasking has on productivity and quality and see if we can apply SMED principles (Single Minute Exchange of Dies) to human processes.

MoreSteam Client Services

Dr. Lars Maaseidvaag continues to expand the breadth and depth of the MoreSteam curriculum by integrating the learning of Lean tools and concepts with advanced process modeling methods. Lars led the development of Process Playground, a Web-based discrete event simulation program. Before coming to MoreSteam in 2009, he was the Curriculum Director for Accenture/George Group and has also worked in operations research and management consulting.

Lars received a PhD in Operations Research from the Illinois Institute of Technology. Prior to his PhD, Lars earned a M.S. in Operations Research and Industrial Engineering as well as an MBA from The University of Texas in Austin.