Resources for Operational Excellence

An Unobstructed View of Customer Requirements

Read More

Making the Case for Organized Process Improvement

Read More

Quality Time Podcast: Bill Hathaway Reflects on a Quarter Century of MoreSteam

Read More

Exploring the Potential of AI in Process Improvement

Read More

Back to Kindergarten: Why Project-Based Learning Gets Results

Read More

Why the Most Critical Phase is Often the Most Overlooked

Read More

Voices in OpEx

- Episode 41: Simulating Success with Dr. Lars Maaseidvaag

- Value Stream Maps to Value Stream Thinking as a Daily Habit

- Accelerating Process Improvement with AI

- Episode 43: Dave Harry is The Process Whisperer

- Episode 44: Lessons From 30 Years of Quality Management with Steve Adams

- How to Apply Lean Thinking to Businesses of Any Size

Teaching Continuous Improvement

Operational Excellence

- Driving Strategic Alignment with the Lean Management System

- Schedule Time for Deep Work

- Sustainable Training Routines for Operational Excellence

- Making Your Strategy Work Across Your Entire Organization

- Trust Equity: The Human Side of Operational Excellence

- Building a Thriving Community of Problem‑Solvers

New to Process Improvement

- A Beginner's Guide: What is Lean Six Sigma?

- Lean Six Sigma Belt Levels Explained

- What is the DMAIC Methodology?

- Good Lean Six Sigma Projects Start with Good Problem Statements

- Don’t Settle for a Paper Belt: Why Projects Are the Heart of Lean Six Sigma Certification

- Episode 38: Keep Asking Why with Eric Olsen

- Lies, Damned Lies, and...Checklists

Project Management

- Aurorium’s TRACtion Success – From Spreadsheets to a Single Source of Truth

- Maximize Project Impact with the Right Lean Six Sigma Project Tracking Tool

- The Perfect Pair: Lean Six Sigma Project Management with Traction & EngineRoom

- Best Practices of Lean Six Sigma Project Management and Tracking Tools

- 900 Project Charters and Counting

- How TRACtion Solves 5 Common Project Management Challenges

Data Analysis & Statistics

- The Future of RCA: Machine Learning-Driven Root Cause Discovery

- Why Every Continuous Improvement Practitioner Should Understand Monte Carlo Simulation

- Understanding Process Capability in Real-World Applications

- A Senior Engineer’s Clever Approach to Sampling Large Datasets

- If You Learn One Statistical Tool for Process Improvement, Make It Control Charts

- Unlocking the Power of Statistical Hypothesis Testing: A Fresh Approach

Upcoming Events

Lean Six Sigma Resources for Continuous Improvement and Operational Excellence

Welcome to MoreSteam's Lean Six Sigma Resource Library—a curated hub of content for professionals focused on process improvement, operational excellence, and continuous learning. Whether you're starting your Lean Six Sigma journey or advancing an enterprise-wide initiative, this page offers a diverse collection of tools and insights to help you solve problems and drive measurable impact.

Explore expert-led webinars, in-depth case studies, white papers, blogs, and podcasts—all designed to help you apply Lean Six Sigma principles in real-world settings. Learn how organizations across industries are using tools like value stream mapping and root cause analysis to reduce waste and improve quality. From foundational concepts to emerging trends in AI and digital transformation, these Lean Six Sigma resources support your growth as a problem-solver and leader in operational excellence. Whether you're looking for inspiration, training, or tactical guidance, the MoreSteam Resource Library is your go-to destination.

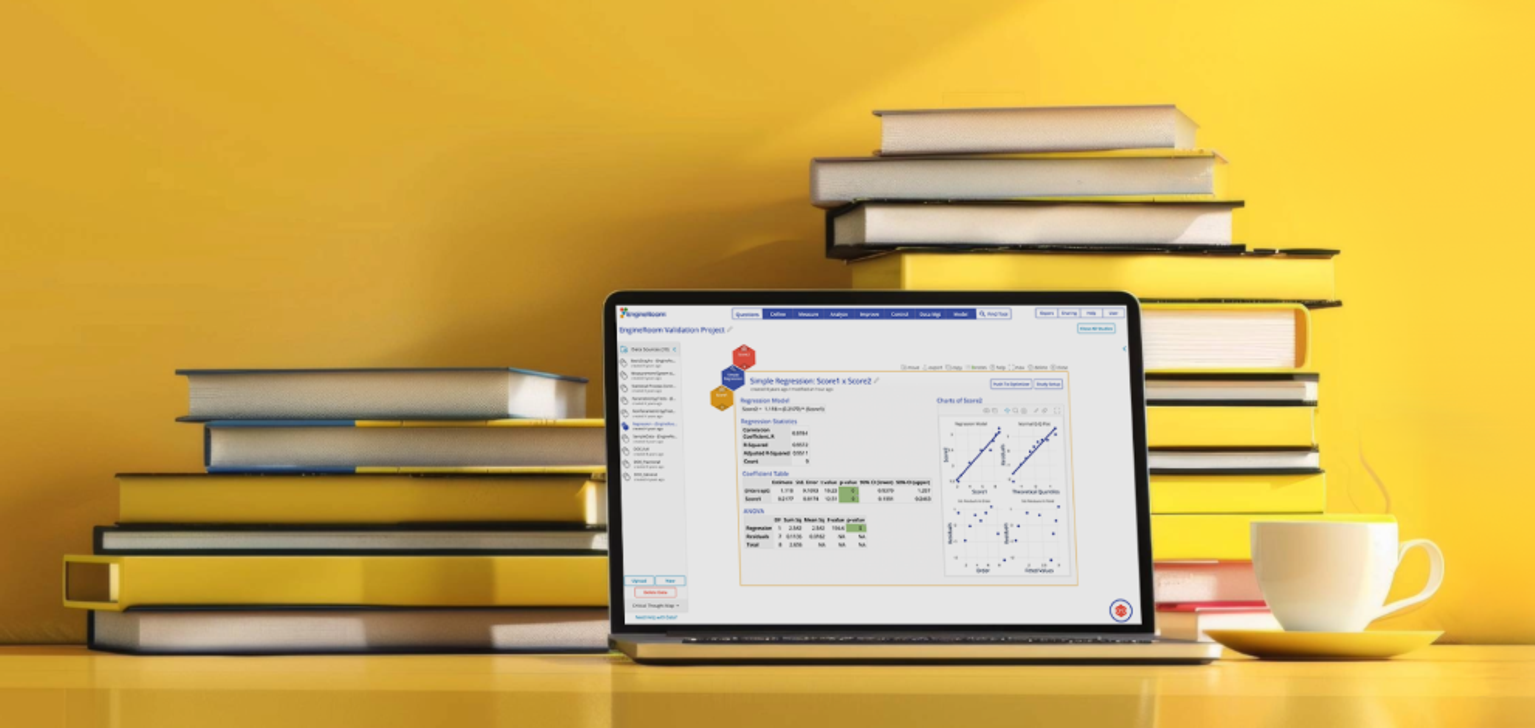

Many of these Lean Six Sigma resources also feature tools developed by MoreSteam, such as EngineRoom for data analysis and TRACtion for project tracking. Whether you're validating a process map or leading a team through DMAIC, these OpEx resources provide practical support for continuous improvement.