Master Black Belt Uses Data to Help YMCA Stay Strong During Pandemic

When the global pandemic disrupted lives and economies, organizations worldwide faced existential challenges. For the YMCA of Greater Cincinnati, the solution came in the form of Keri Brewer, a Master Black Belt with a passion for using data to solve complex problems and improve lives. Brewer’s leadership not only helped the YMCA overcome significant obstacles but also provided a blueprint for resilience that has inspired nonprofits across the country.

As a former Master Black Belt at Bridgestone, Brewer trained and coached hundreds of leaders at a Fortune 500 company, honing her expertise in Lean Six Sigma methodologies. Today, she applies those same principles to one of the nation's largest nonprofit organizations, helping it operate with greater efficiency and impact.

The work has been fulfilling, she says, but it became even more critical in 2020 when the pandemic forced the YMCA to rethink its entire operational model. With memberships plummeting and financial pressures mounting, Brewer spearheaded a restructuring effort that not only stabilized the YMCA of Greater Cincinnati but also influenced regional YMCA associations nationwide. Lean Six Sigma tools guided the creation of a detailed, data-driven plan that addressed pressing challenges and positioned the organization for future success. This plan was later adopted by Y-USA as a best practice and shared across the network.

We spoke with Brewer to learn more about her journey from the corporate world to the nonprofit sector, the monumental restructuring project, and her perspective on bringing Lean Six Sigma thinking to a mission-driven organization.

Tell us about your transition from Bridgestone to the YMCA of Greater Cincinnati. What led to the change?

I left Bridgestone in 2014. I had climbed the corporate ladder pretty quickly, but I could feel the life seeping out of me. I needed some time off to focus on myself and think about what I wanted to do next.

I started working at the YMCA as a yoga teacher while picking up a few Six Sigma consulting contracts on the side. Eventually the CEO at the Y, Jorge [Perez], found out as I was a Six Sigma Black Belt – he's trained as a Black Belt himself and is an avid supporter of the DMAIC process. I started doing some small consulting projects for them and before long he said, "Why don't we stop paying you like a consultant and just put you on the payroll?"

When you took on the new role, how did you incorporate more Lean Six Sigma thinking into the organization?

I started as a consultant by doing a needs assessment, and then I created a custom training program for the Y. It was just a one-day thing, covering the basic DMAIC toolset. During the next 16 months or so, I trained around 40 people — I call them Light Greens, because the curriculum is somewhere in between Yellow Belt and Green Belt.

Then In 2020 we rolled out Sponsor and Champion training, which goes over S.M.A.R.T goals, how to ask good questions, execute a successful meeting, and an effective tollgate. So far, we've trained about 16 people as Champions and Sponsors.

What are some of the biggest differences you experienced training people at the Y compared to the companies you worked at previously, where Six Sigma was more ingrained in the culture?

In the corporate world, a lot of times you'll find yourself alongside brilliant people who are a little difficult to work with. There's a lot of politics and competition. What I've experienced in the nonprofit world is different. Everyone has a giant heart, but not necessarily the same level of business acumen.

The phrase I heard the most when I first started here was "I believe" or "I feel it in my gut." It was a huge cultural shift for us to go from saying "I feel" to instead saying "the data tells me," or "I know this because of the data."

It was a huge cultural shift for us to go from saying 'I feel' to instead saying 'The data tells me.'

When training employees who have limited Lean Six Sigma experience, is there a danger of overcomplicating? Some people default to an overemphasis on tools rather than pragmatic data-driven problem-solving.

I couldn't agree more. While I believe there are certain fundamental tools without which projects will likely fail, it doesn't have to be rocket science. Keep it simple, stupid!

For example, we rarely have a need for hypothesis testing beyond basic T-test, so I didn't even incorporate that in our Analyze phase. Those concepts are too overwhelming for most of our employees. Pareto, Fishbone, 5-Why, and the occasional control chart serve our purposes well enough.

One big change you're implementing at the Y is using MoreSteam's project management software, TRACtion, for data analysis. How has that impacted the organization?

We've just started rolling it out, but it's such an important step for us. I worked with MoreSteam in the past so I know a lot of people on the team, and one day I was talking with [Director of Business Development] Gabe [Turk] about how beneficial TRACtion would be at the Y. However, because we're a nonprofit, I knew we'd never be able to afford it. We just don't have that kind of money.

That was passed along to MoreSteam, and before long I heard Bill was willing to donate 10 TRACtion licenses to us. I went to my CEO [Jorge] right away and told him what an amazing opportunity this is. After he got to see a full demo, he called me and said "I knew this would be good, but I didn't realize just how big of a game-changer it is."

Let's talk about last year and how Covid-19 impacted your business. Every organization faced massive hurdles during the pandemic, and I'm sure the YMCA was no exception.

Yeah, it was a massive shift for us. We have 12 core facilities in Northern Kentucky and Southern Ohio, plus 60+ childcare centers. When Covid hit, our membership dropped to <70% of what it had been. We had to downsize dramatically, cutting our workforce by about half.

At first I was one of the people who got laid off, but about three weeks later Jorge called me and said they needed help to restructure the entire organization. He asked if I could use data and my background to help figure it out.

How was the restructuring guided by Lean Six Sigma thinking?

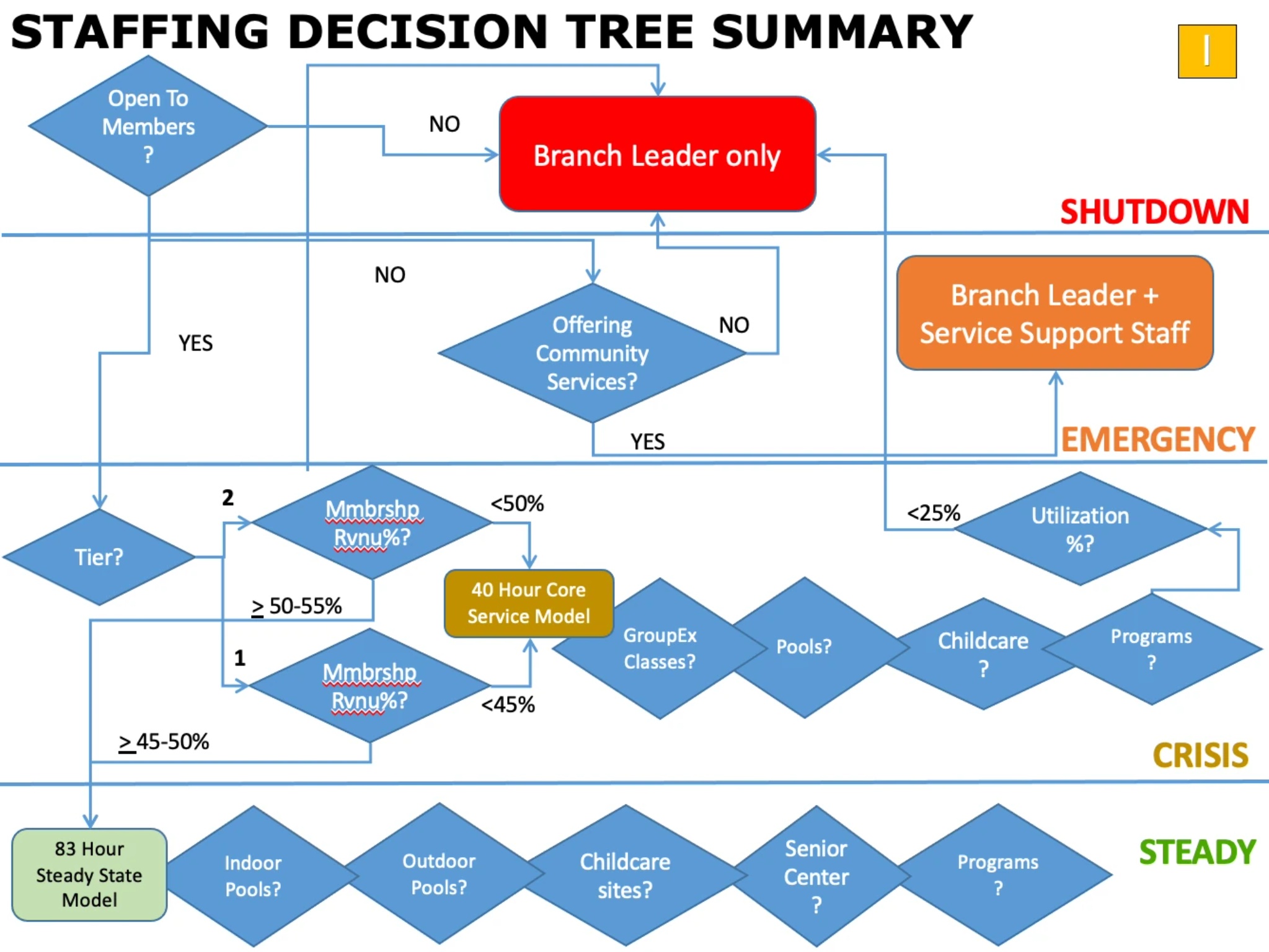

We drew upon LSS thinking most effectively in the use of process mapping, value matrices, Pareto, and standardization. We analyzed a lot of data, figuring out what was high-value & low-effort, and what was low-value & high-effort, so we could make informed decisions.

We ended up creating a really thorough presentation with about 150 slides, detailing the entire approach. That plan has now been adopted as a Y-USA best practice and shared with numerous other Associations who are likewise struggling financially.

Creating a standard of work that's being adopted across the country has to be a good feeling. How did you first approach something as massive and time sensitive as adjusting during the pandemic?

Thankfully, we weren't just looking at dollars saved. We used Lean Six Sigma tools to analyze data and figure out what our customers were looking for. People were stuck at home, but they still wanted to work out. I don't think we'll ever be able to compete with Peloton or Apple, but one thing we have that they don't is that personal connection. That heart-to-heart relationship you build when you go to the Y to take a class from your favorite instructor.

Fortunately for us, the big Peloton boom started happening at the end of 2019 so we were already responding to that. We had a Six Sigma project exploring how to create a virtual studio and offer classes online. We call it Y Stream.

Because we already had that in the works, we were able to get a virtual studio up and running less than six weeks after the close of our facilities.

Beyond increasing your virtual presence, what are some of the other major changes you implemented?

We no longer had the luxury of having a separate staff for each location. We had to shift the way our employees worked, so that we shared resources more than we ever had before. We ultimately ended up created two new groups of locations:

- Communities — A grouping of two nearby branches that's staffed by one team of employees

- Neighborhoods — Slightly larger groupings of nearby locations that can share resources with each other

Those changes made a huge difference in how we work. They changed the way we recruit, hire, train...everything. Team members are now asked to do more, and certain tasks are taking on greater significance. Every position comes with a little more responsibility which is actually helping us find the talent we need to really serve our community as effectively as possible.

Before we wrap up, can you share a little bit about how this new role has impacted you personally? You seem to really enjoy the work.

I absolutely love it! I feel like every project I'm working on really matters. I'm helping a team increase the quality of swim lessons and also the quality of our before-and-after-school childcare. We are working hard to make our nonprofit dollars stretch as far as they possibly can.

The work we're doing every day helps people live happier, healthier lives, and that's really important to me. Meaningful work is a great feeling.

(This interview has been edited slightly for length and clarity.)

Master Black Belt Expertise in Action

Keri Brewer’s work as a Master Black Belt at the YMCA of Greater Cincinnati demonstrates the transformative power of Lean Six Sigma to drive meaningful change, even in the face of unprecedented challenges. By applying data-driven strategies and fostering a culture of continuous improvement, she has not only strengthened the YMCA locally but also influenced nonprofit organizations nationwide. Brewer’s story serves as an inspiring example of how a Master Black Belt’s expertise can make a lasting impact, proving that Lean Six Sigma isn’t just for the corporate world—it’s a tool for creating stronger, more resilient communities.

MoreSteam's Enterprise Process Improvement platform includes the tools, training, and software you need to transform your organization, large or small, into a problem-solving powerhouse. Our products are trusted by over half of the Fortune 500 and by other organizations and universities worldwide. When you partner with MoreSteam you gain a team dedicated to helping you succeed.