Building a Thriving Community of Problem‑Solvers

How Greif Rapidly Scaled Lean Six Sigma with MoreSteam

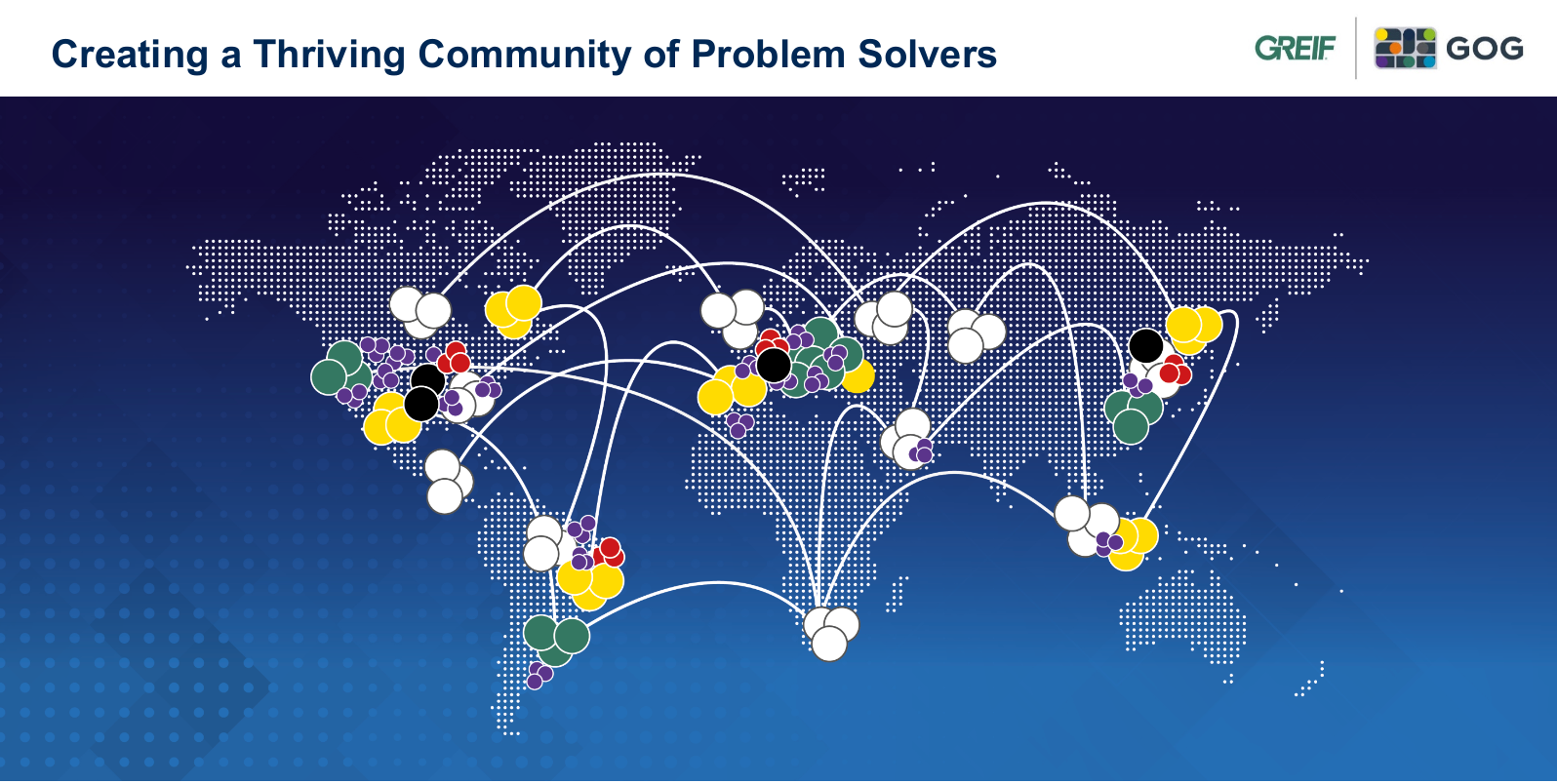

Businesses don’t need journeys; they need change now. That's the mindset of Toby Locke, Greif's Vice President of Global Operational Excellence. In under three years, Greif transformed a small pilot of 12 Green Belts into a global, on‑demand Lean Six Sigma (LSS) program spanning 26 countries, 200+ facilities, and 14,000 colleagues. Executive‑level engagement, a "rapid‑deployment" mindset, and a close partnership with MoreSteam turned initial momentum into enterprise‑wide capability and measurable savings.

Without the ELT [Executive Leadership Team] we would not be as successful as we are today. [...] They’ve been there every step of the way.

Company Background & Challenge

Approaching its 150th anniversary, Greif is a global leader in industrial packaging with a profound legacy of craftsmanship, reliability, and sustainability. At the core of its "Build to Last" strategy are four pillars, one of which is creating thriving communities. Creating thriving communities shapes how Greif invests in its internal teams, aiming to build a culture where employees can grow, contribute, and thrive.

Operational Excellence is a key enabler of that vision. While the organization had experienced several waves of Operational Excellence (OpEx) activity over the years, many efforts started strong only to lose steam. When Toby Locke joined Greif, the mandate from Senior Vice President, Chief Operations Officer Kim Kellermann was clear: rebuild OpEx and make it stick.

Solution: Pilot First, Then Pull

Locke's early vision was shaped by a conversation with MoreSteam President Peg Pennington. He refined the vision with Kim Kellermann, who encouraged a pilot-first approach to demonstrate value. That early alignment between internal and external leaders laid the foundation for what would become a global transformation.

Locke's approach was simple but effective: start small, prove impact, and build pull. They did this by:

- Piloting a cohort of 12 high‑performing Green Belts using MoreSteam's eLearning and coaching model.

- Showcasing early wins to senior leaders and business units.

- Letting demand pull the program across the enterprise instead of pushing training where it wasn't wanted.

We started with this little snowball at the top of the hill. By the time months passed and people saw others get celebrated, it really took off.

The pilot's results spoke for themselves. It delivered strong outcomes from early high-performers, and the Executive Leadership Team (ELT) had the chance to see it all along. The pilot generated strong results, and the ELT became a visible champion. Early success stories helped employees envision what Lean Six Sigma could do for them.

Rapid Deployment, Not a “Journey”

Locke and the leadership team rejected the idea of a slow five‑year transformation. Rather than prescribe a linear rollout, the team went where there was pull. When areas of the business expressed interest, they were prioritized. If not, resources weren't wasted. The early strategy emphasized flexibility and responsiveness.

Following the idea of applying Lean Six Sigma principles to their strategy, Locke modified Greif's training program. Structured initially in cohorts, the Lean Six Sigma program evolved into a continuous, on-demand flow, eliminating "batching" their training into cohorts. This change better met participants where they were. The shift was significant for employees with limited bandwidth during the workday, like production supervisors.

We decided to meet individuals where they are.

Scaling with MoreSteam

Greif's rapid expansion was made possible by MoreSteam's scalable platform and strong partnership:

We were able to put our White and Yellow Belt programs at the click of a button, making them available to 14,000 colleagues worldwide.

White and Yellow Belt training was embedded directly into Greif University, giving global teams immediate access. As demand grew, Greif expanded Green and Black Belt offerings, with new pilots underway to include Green Belt certification in Portuguese-Brazilian.

Programs now reach 26 countries, with multiple languages supported and more in development. Digital badges and LinkedIn-ready visuals amplify recognition and visibility across the organization.

MoreSteam's tools, content, and team allowed Greif to scale quickly without sacrificing quality. As participants progress, many share that the program has taken their understanding to a new level, far beyond what they learned in traditional training or university coursework.

The partnership continues to evolve, helping Greif sustain the gains and expand the program over time. The program's quality, rigor, and unified global standard are now widely recognized across the business.

That kind of global consistency, scale, and quality wouldn't have been possible without the proper support:

You can't create one global enterprise standard without a good partner like MoreSteam… and we didn't have the bandwidth to do it alone.

Building a Thriving Community

Greif's LSS program is more than training, it's a culture shift aligned with their Build to Last strategy. One of the pillars of that strategy is creating thriving communities and Locke shaped the program to reflect that by cultivating "a thriving community of problem-solvers."

The cultural infrastructure to support that includes:

- Quarterly town halls and SBU-level events to recognize new Green and Black Belt graduates

- A daily GREIF News broadcast sharing Lean Six Sigma program milestones and photos of recipients

- The SPARK platform, which allows colleagues to recognize each other, is often used to celebrate certifications and project impact, with visibility across the entire organization

- Handcrafted plaques awarded upon certification completion, personalized and presented in person whenever possible

- Public celebration on LinkedIn, where many employees independently post their accomplishments

This multi-layer approach to recognition creates real pull. As colleagues see peers being acknowledged and celebrated, they are motivated to get involved, a dynamic Toby described when reflecting on the program's early momentum: "People started seeing people get celebrated... and said, 'Hey, I want to be a part of that.'"

As Locke said, "It's a huge personal commitment to go through this program. When someone finishes, they're proud of it—and we make sure the whole organization sees and celebrates that."

Addressing the Coaching Challenge

With success came growing pains, especially in providing high-quality coaching support. As more employees enrolled, it became clear that bandwidth for mentoring was a constraint:

"If you asked me what our greatest challenge has been, it's two things. One, giving colleagues time to do the work. And two, having enough coaches to guide them effectively."

After early momentum led to rapid enrollment, now Greif deliberately paces growth to ensure quality over quantity. Of Toby's 10 direct reports, 9 have completed Green Belts, and 7 have achieved Black Belt certification, expanding the team's capacity to lead and coach new learners.

You don’t master Lean Six Sigma by earning a certificate—you master it by teaching and coaching others. That’s what builds real capability.

Results to Date (Year 3)

In under three years, Greif has built a global Lean Six Sigma capability that reaches 14,000 colleagues across 26 countries. The program has certified 366 colleagues from White through Black Belt, with 74 active Green Belts and 7 active Black Belts currently driving improvement work.

| Metric | Achieved |

|---|---|

| Metric: Certified Colleagues | Achieved: 366 (White Belt - Black Belt) |

| Metric: Active Green Belts | Achieved: 74 |

| Metric: Active Black Belts | Achieved: 7 |

| Metric: Countries Engaged | Achieved: 26 |

| Metric: Languages Offered | Achieved: 4 (and expanding) |

Greif's focus on quality over quantity sets the program apart from past initiatives. Certification isn't a paper handed out to just anyone. A Lean Six Sigma certification at Greif is earned through real project work, sharp thinking, and meaningful contributions to the business. And when someone reaches that milestone, Greif doesn't let it go unnoticed. The financial impact is already significant, and with growing internal expertise and Master Black Belts on the horizon, Greif is positioned to drive even greater value at scale.

Lessons Learned

- Secure hands‑on executive sponsorship. "The ELT is every bit as engaged today as when we started."

- Pilot, prove, then pull. Early wins build credibility and organic demand.

- Choose the right people—and the right partner. High performers paired with MoreSteam's robust rubric set the tone for lasting quality.

- Prioritize quality over quantity. Scaling must be matched by coaching support.

- Celebrate relentlessly. Recognition fuels engagement and strengthens culture.

- Be willing to pivot. The program evolved from pilot to cohorts to on-demand to meet workforce needs.

Looking Ahead

Locke envisions a future where Master Black Belt champions are embedded across every region and SBU, driving transformation at scale:

"We've only scratched the surface. If we stay on this trajectory, the program will be game-changing in five years."

With a foundation rooted in strategic alignment, community celebration, and a strong partnership with MoreSteam, Greif is well on its way to embedding Lean Six Sigma into the DNA of its global operations—creating lasting value, thriving teams, and better work for everyone.

At the end of the day, Lean Six Sigma is about helping PEOPLE (our colleagues) – Make Things Better

Vice President of Marketing • MoreSteam

Lindsay Van Dyne is responsible for developing and executing MoreSteam’s marketing strategy. She brings a deep understanding of Lean Six Sigma, having served as MoreSteam’s eLearning Product Manager for the company’s comprehensive suite of Yellow, Green, and Black Belt courses. Over the years, she has attended dozens of industry conferences, webinars, and workshops, gaining firsthand insight into the evolving needs of continuous improvement professionals.

Her marketing experience includes technical aspects of search engine optimization (SEO), digital content strategy, lead generation, website development, event management, and partner relationships. Lindsay holds a B.S. in Chemical Engineering from the University of Notre Dame and a B.S. in Computational Physics and Mathematics from Bethel College.

Lean Six Sigma Program Overview

- Over 1,000 Participants

- Representing 26 Countries

- Over 290 Total Certifications

2025 Greif Global OpEx Team Roadmap

1. Building a Global OpEx Team

Greif is uniting under One Greif by strengthening its continuous improvement culture, advancing LSS Black Belt capabilities, refining A3 execution, and fostering a global community of problem solvers.

2. Create Value for Our Customer

Through global projects and strategic Kaizen events, Greif delivers results that matter. Best-in-class programs, GEMBA training, and best practice sharing keep teams working smarter and in sync so customers see value in every interaction.

3. Drive a Lean Thinking Culture and Help People

Greif builds confident problem-solvers through targeted LSS cohorts and a sustained global program with engaged alumni, positioning the company as a leader in Lean thinking.

4. Sustain an Aggregation of Marginal Gains

Small wins add up to lasting impact. With more than $4.5M in annual savings, a robust A3 project pipeline, and smarter project selection through quadrant analysis, continuous improvement becomes a sustained habit.