Lean System as an Animal

December 20, 2025If you have been involved in process improvement, you’ve probably seen Lean principles, practices and systems presented as building blocks that create a structure, typically a house. This physical construct is useful to highlight the components and functional hierarchy of a lean system. It’s simple to understand since we’re all familiar with the basics of building a structure on a foundation, with the goal as the highest element of the building. Do a quick search of “Lean House” and you will see images like this:

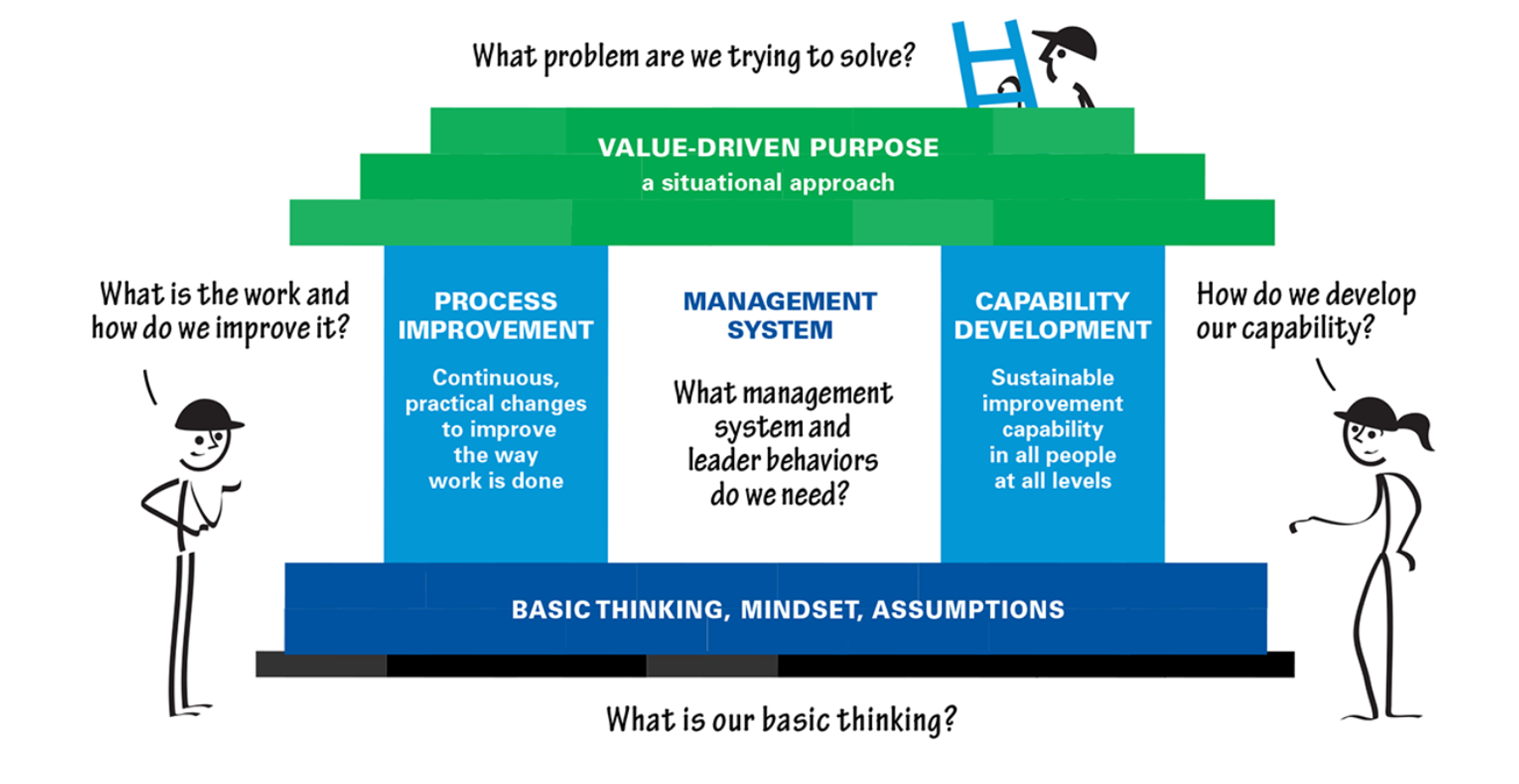

Tom Paider of Nationwide made the point at MoreSteam’s most recent Best Practices for Operational Excellence conference that (paraphrasing) “everybody has a lean house diagram of some sort.” For example, here’s a closer look at the popular LEI Lean Transformation Framework. It’s very concise and useful.

The houses are all nice, but we believe that “all models are wrong but some are useful”, so despite being useful, perhaps this building metaphor is limiting. In the spirit of continuous improvement, let’s consider whether there might be a better approach. For starters, what do we want our lean management system (or operational excellence system if you prefer) to achieve? Don't we actually want our lean management systems to be dynamic and fast and adaptive? Don’t we want it to learn and grow over time? Does a static building diagram best represent our intent? And how might this temple of lean subtly influence our mental model about the system we are trying to build? At a minimum, we should add wheels and turn the house into an RV so that it can move.

That’s better, but it’s still very limiting.

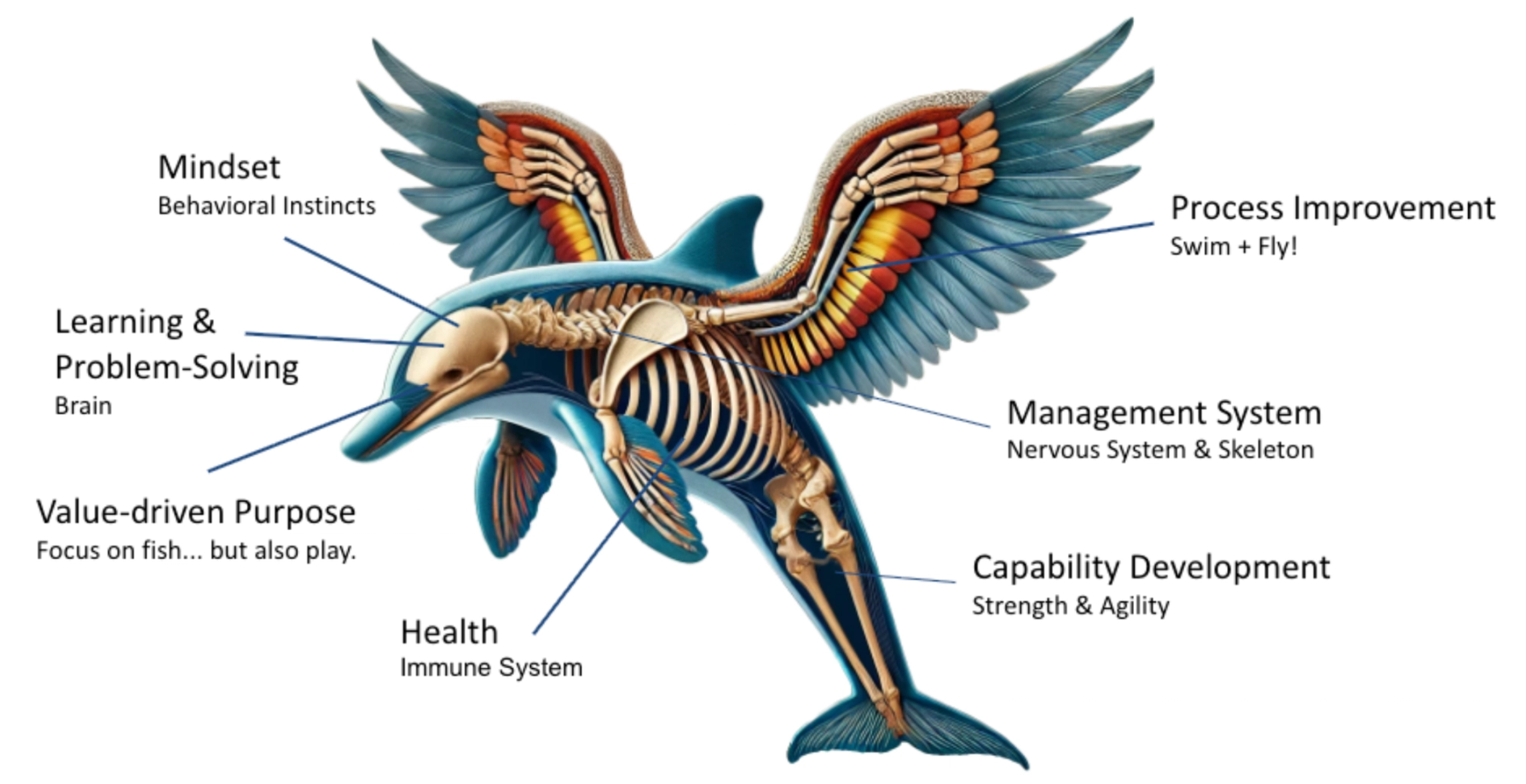

To achieve sustainable operational excellence in an environment of constant, wrenching change, we need to represent a system that grows…and adapts…and heals when injured…and learns…and works together as a team…and competes. We’re contemplating a complex system of humans and human interactions, so it’s organic. Perhaps our system is better represented as an animal of some sort–or group of animals–than as a physical structure.

Working with that idea, the appropriate animal metaphor could be a herd of deer or even bison. But then what business really aspires to be an herbivore given plant-eaters’ position on the food chain? Our example should really be a predator. But is there a friendly predator? Toads seem friendly, and they are fearsome carnivores in their own right, but they are not very dynamic. So what about dolphins? They are highly intelligent, are actually fierce and successful predators, and they work together (and don’t eat humans). Let’s see how this could develop.

Here’s how we might label the components of our lean animal to represent a lean system:

- Value-Driven Purpose - Focus on Fish (but also Play)

- Management System - Bones and Nervous System

- Capability Development - Muscles for Strength & Agility

- Mindset - Behavioral Instincts

- Durability & Self-healing - Immune System

- Learning & Problem-Solving - Brain!!!

But why stop there? We could improve the dolphin…by adding wings! That’s a process improvement for sure.

One last thing: operational excellence is a team sport, so it’s not just one dolphin, it’s a pod. Now the metaphor is complete. It’s a little out there, but doesn’t it make more sense than representing our efforts as a Greek Temple? Who wouldn’t want to be a flying dolphin?

CEO • MoreSteam

MoreSteam is the brainchild of Bill Hathaway. Prior to founding MoreSteam in 2000, Bill spent 13 years in manufacturing, quality and operations management. After 10 years at Ford Motor Co., Hathaway then held executive level operations positions with Raytheon at Amana Home Appliances, and with Mansfield Plumbing Products.

Bill earned an undergraduate finance degree from the University of Notre Dame and graduate degree in business finance and operations from Northwestern University's Kellogg Graduate School of Management.