Why Every Continuous Improvement Practitioner Should Understand Monte Carlo Simulation

October 1, 2025Let’s say you’re managing inventory for a retail chain about to roll out its winter collection. The forecast says you’ll sell 75,000 coats. Seems straightforward. Except that you know in the back of your mind that last year's forecast left you with warehouses full of unsold stock. The year before that, you ran out halfway through December. You can’t control the weather, the economy, or your competitors’ pricing. But you still have to make the call. How many coats do you order this year?

That’s exactly the kind of situation where Monte Carlo simulation shines. Monte Carlo simulation can’t tell you whether your forecast is right or wrong, but it can help you understand what could happen if it’s off. When the future is uncertain, Monte Carlo shows you the full spread of possible outcomes so you can make decisions with a clearer view of the risk involved.

What a Monte Carlo Simulation Really Does

At its simplest, Monte Carlo simulation is about running an experiment many, many times using random sampling to determine the probability of different outcomes in an uncertain process. You feed in the uncertainty that already exists in your process: variation in cycle time, machine downtime, defect rates, customer demand. Then you let the simulation roll the dice thousands of times.

The result isn’t a single forecast. It’s a distribution that tells you the odds: maybe there’s a 60% chance you’ll sell between 70,000 and 80,000 coats, a 25% chance demand will surge past 90,000, and a 15% chance it drops below 65,000. That’s a very different conversation than saying, “we expect to sell 75,000 coats.” It gives you visibility into other possible outcomes and the confidence to plan for it.

How Others Are Using It

Practitioners across industries are pulling Monte Carlo simulation into their improvement work. In one hospital’s quality improvement project, a team used Monte Carlo to help prioritize which intervention would make the biggest impact in recovery time. They analyzed several potential drivers of long post-operative stays in the PACU and found that, although postoperative nausea and vomiting were highly correlated with delays, eliminating moderate opioid use offered the greatest expected reduction in total recovery time. Instead of guessing which initiative would have the most impact, they used simulation to let the probabilities decide and then focused resources where they’d get the best return.

Manufacturing teams are applying the same logic to operational decisions. A cutting tool plant, for example, combined historical production rates with downtime data and used Monte Carlo simulation to generate more realistic lead-time predictions. They moved from vague promises to a quantified picture of delivery risk, which helped them reduce backorders.

Even Agile software teams have embraced it. One team started using Monte Carlo simulation on past throughput data to forecast future delivery with confidence ranges. Instead of promising that a release will “probably” be done by the end of the quarter, they can say there’s an 85% chance of finishing by week eleven and a 95% chance by week twelve.

Even in process improvement business cases, researchers have paired Monte Carlo simulation with Bayesian networks to estimate ROI. Rather than asserting, “This project will save $500,000,” teams can say, “We’re 80% confident savings will land between $450,000 and $520,000. That nuance is powerful. It's that kind of probabilistic conversation that builds trust.

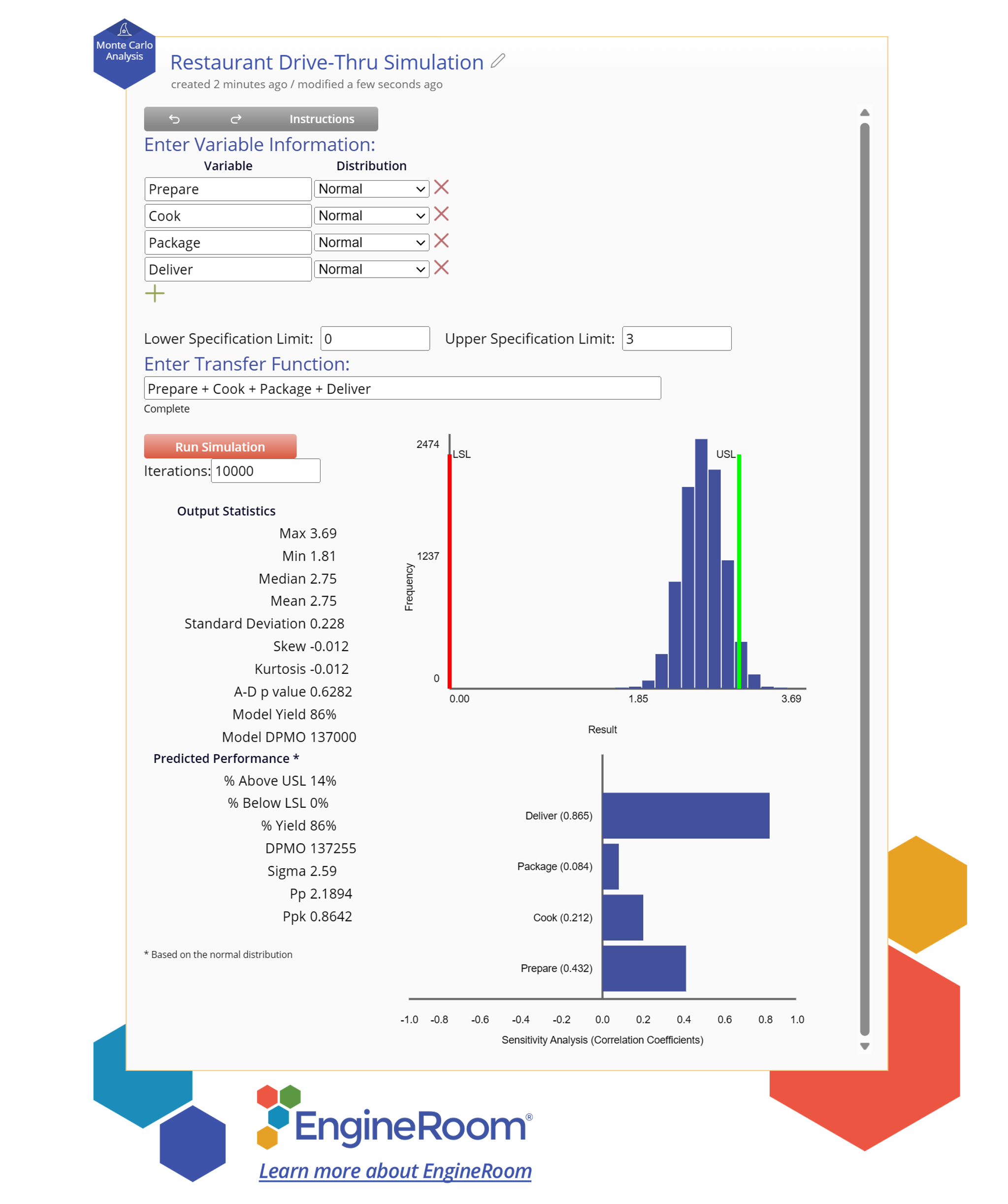

A sample Monte Carlo Simulation from EngineRoom® featuring a restaurant drive-thru simulation.

Why Monte Carlo Simulation Belongs in Every Continuous Improvement Toolkit

An important aspect of continuous improvement is reducing unwanted variation. SPC charts, Design of Experiments (DOE), and regression are all ways of seeing and reducing variation. Monte Carlo simulation belongs right alongside them because it takes the variation you already measure and projects how it plays out in outcomes.

For the practitioner, it changes the quality of the conversation. Instead of defending a single forecast, you can lay out a range and talk about probabilities. That builds credibility with finance, operations leaders, and customers. It also helps you compare improvement ideas by running scenarios side by side to see which has the best chance of hitting your target.

And it’s more accessible than ever. With the right tools, you don’t need a statistics degree or custom code to get started. Simulation engines like the Monte Carlo Analysis tool in EngineRoom® handle the heavy lifting. Your job, then, is just to define the uncertainties honestly either through process knowledge or from collected data and then interpret the story the results tell.

Where to Begin with Monte Carlo Simulation

If you’re new to Monte Carlo simulation, start small. Pick one decision you currently make with an average: lead time, defect rate, or cost savings. Gather a bit of historical variation data, plug it into a simple simulation, and see what the distribution of outcomes looks like.

Once you’re comfortable with simple simulations, take it further by integrating Monte Carlo with models you’ve already built through DOE. Reporting an average at new target settings doesn’t guarantee every future run will stay within specification. Your process output still has random noise, and your input variables carry variation too.

Using Monte Carlo simulation, you can combine your DOE model, new target input settings, and input variable variation to generate a more realistic distribution of process outcomes. The result is a far more accurate picture of what performance will look like when your process runs under real conditions.

For a step-by-step walkthrough, see our Monte Carlo Analysis Tutorial.

Hands-On Webinar: Run Your First Monte Carlo Simulation

Because we believe every CI professional should have this tool in their kit, we’re hosting a hands-on webinar dedicated to Monte Carlo simulation. We’ll walk through:

- How to set up a Monte Carlo Simulation

- How to interpret the outputs

- How to use the results to guide real decisions

We’ll also share live examples drawn from actual improvement projects so you can see the practical impact.

Closing Thought

Averages are easy, but they can be dangerous. They hide the tails of the distribution from the delays, the overruns, the defects that drive customers away. Monte Carlo simulation puts those tails back into view. It lets you see around corners, prepare honestly for uncertainty, and speak the language of probability that leaders and customers respect.

If you’re ready to make better promises and back them up with data, Monte Carlo simulation is a great place to start. Join us for the webinar and see how it can change the way you plan, decide, and deliver.

Vice President of Marketing • MoreSteam

Lindsay Van Dyne is responsible for developing and executing MoreSteam’s marketing strategy. She brings a deep understanding of Lean Six Sigma, having served as MoreSteam’s eLearning Product Manager for the company’s comprehensive suite of Yellow, Green, and Black Belt courses. Over the years, she has attended dozens of industry conferences, webinars, and workshops, gaining firsthand insight into the evolving needs of continuous improvement professionals.

Her marketing experience includes technical aspects of search engine optimization (SEO), digital content strategy, lead generation, website development, event management, and partner relationships. Lindsay holds a B.S. in Chemical Engineering from the University of Notre Dame and a B.S. in Computational Physics and Mathematics from Bethel College.