Why Simulation is the Missing Ingredient in A3 Training

February 18, 2026That morning in Ohio was bitterly cold, the kind of cold that makes you wonder whether anyone will actually venture out, let alone show up ready to learn. I remember thinking there was a decent chance the room would be half empty. Instead, we walked into a full house at The Ohio State University, brought together through the Center for Operational Excellence, and it set the tone for a really energizing day.

This workshop was designed to be hands on from the start. Participants completed an A3 overview in advance, which meant we did not have to spend the day defining terms or walking through templates. We were able to focus on what A3 is really about, which is going to the gemba, asking good questions, and learning how to tell a clear story with data. To simulate that experience, we used the Drury Lane Muffin Company manufacturing simulation as a virtual gemba.

What I love about Drury Lane is how real it feels. Participants hear from people across the process and quickly realize that no two perspectives are the same. Maintenance has one explanation. Operators have another. Day shift and night shift see the world very differently. At first, it feels overwhelming, and that is exactly the point. Improvement work rarely starts with a neat, orderly picture. You have to sort through conflicting information, listen carefully, and combine what you hear with the data in front of you to make sense of what is actually happening.

We intentionally divided the room by experience level, asking people to self-select as guides or explorers, so that every table had a mix of perspectives. That structure led to some really rich conversations within the teams. As I walked around, I heard people sharing how improvement work shows up in their organizations, what works well, and where they still struggle. There was a lot of learning happening peer to peer, which is always one of my favorite things to see.

Another moment that stood out to me was how people chose to work. We gave teams the option to build their A3s physically using flip charts and Post it notes or digitally using Mural. Most teams chose Mural, even though many had never used it before. They were comfortable experimenting, pulling charts from EngineRoom, and organizing their thinking in a way that made sense to them. We did not spend time teaching tools or worrying about downloads. The focus stayed where it belonged, on thinking clearly and working through the problem.

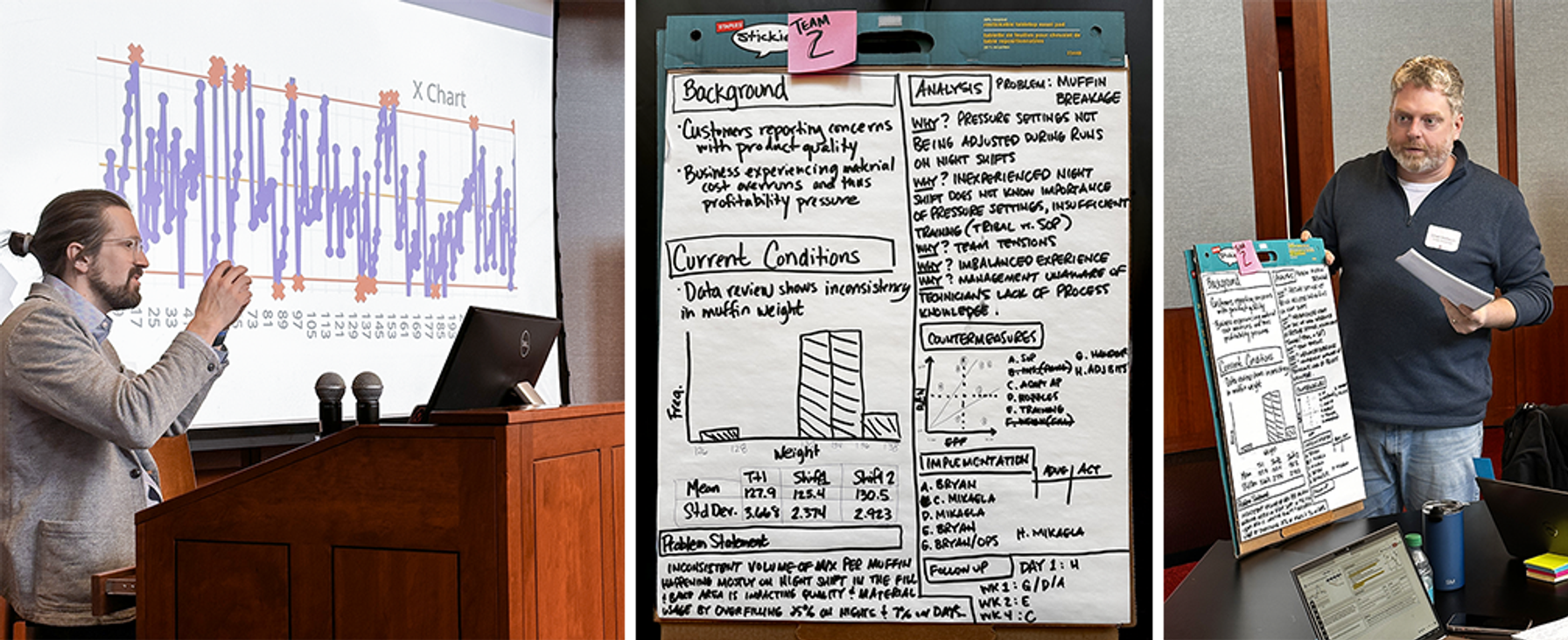

As the A3s took shape, the storytelling became more interesting. Some participants clearly had deep statistical intuition and were able to articulate ideas about variation, targets, and process capability in ways that elevated the discussion for their teams. Others were still building confidence with data analysis, but the simulation supported them well enough that no one got stuck. The structure allowed people to learn from each other, and you could see understanding deepen as the day went on.

One of the most meaningful discussions came from the storyline itself, particularly around how we talk about problems. The simulation includes the familiar tension between day shift and night shift, and more than once I heard people catch themselves mid sentence and rethink their language. Saying there is a problem on the night shift feels very different from labeling something as a night shift problem. Those distinctions matter, and they opened the door to conversations about respect, blame, and how improvement efforts are received by the people doing the work.

When teams moved into the Improve phase, several went beyond proposing ideas and started thinking about how those changes would actually live in the organization. One team, in particular, tied their countermeasures directly to daily huddle boards and ongoing management routines. That connection back to the lean management system is critical, because improvement does not end when the A3 is finished. It has to become part of how the work is managed every day.

By the time teams presented their A3s, it was clear that the value of the day was not just in the outputs on the wall or in Mural. It was in the conversations, the shared discovery, and the way people challenged their own assumptions along the way. The partnership with the Center for Operational Excellence made that possible by bringing together professionals from different organizations who were willing to learn from one another and think more deeply about how continuous improvement shows up in their own environments.

I left the workshop reminded of why simulations like Drury Lane are so powerful. They create a space where technical skills, people skills, and systems thinking come together in a way that feels real, engaging, and immediately applicable. That is where the real learning happens, and it was great to see it unfold in a room full of people who showed up ready to do the work, despite the cold. If you are interested in learning more about the Drury Lane Muffin Co. simulation, or in using it as a way to practice A3 thinking and DMAIC in your own organization, feel free to send me a message. I am always happy to talk about how we can create learning experiences that make improvement work feel more real and more connected to the work people do every day.

President • MoreSteam

Peg Pennington joined MoreSteam's executive team in 2018 and today leads all company operations as President. Previously, Peg was the Executive Director of the Center for Operational Excellence at The Ohio State University, where she helped shape the Master of Business Operational Excellence ('MBOE') program and strengthen standards for Lean Six Sigma certification. She serves on the board of directors for the Lean Enterprise Institute (LEI). A recognized voice in operational excellence, Peg speaks at over a dozen national conferences each year and leads product workshops.

Before joining MoreSteam, Peg was the Executive Director of the Center for Operational Excellence at The Ohio State University. Peg holds a bachelor’s degree in finance from Michigan State University and an MBA from the University of Dayton.