Engaged workforce leads to reduced wait times, happier customers

March 30, 2020"Connecting Arizona. Everyone. Everywhere. Every Day."

That's the mission of the Arizona Department of Transportation (ADOT). When you visit one of their Motor Vehicle Division (MVD) offices, you'll likely see it prominently displayed on signs throughout the building. What you won't be able to see is the ongoing effort happening behind the scenes to accomplish that mission as efficiently as possible.

It's true – MVD employees are passionate about reducing your wait time. And now, thanks to process improvements under the Arizona Management System (AMS), they're reducing those wait times more effectively than ever before. They even have the stats to back it up.

In July 2016, the average MVD customer experience lasted 54 minutes. One year later, the average time was below 30 minutes. Added together, reduced wait times saved Arizona customers an estimated 1.3 million hours in 2017.

How did they accomplish such a monumental shift? For starters, they asked every employee for advice. Emphasis on "every."

ADOT's director, John Halikowski, challenged the 3,600+ employees to complete at least 7,200 Kaizen ideas annually — an average of two per person, with 100% participation expected.

"We talk about employee engagement a lot, especially when we were first starting AMS," said Kismet Weiss, the Leader of the Office of Continuous Improvement for ADOT. "Our Employee Engagement Score (Net Promoter) remained around the same level for several years. But since we began adopting a Kaizen mindset and let the people who do the work develop the best way to work, that score has almost doubled."

Kaizens and Gemba Walks have become a staple of every MVD office. Employees have already implemented hundreds of ideas, ranging from big (a new way to share important documents with other offices) to small (labeling shelves in the supply closet). The only constant is that new suggestions keep rolling in.

Eliminating wasted time and effort is one of the top priorities, with space on every Kaizen form to indicate the specific type of waste that would be eliminated or reduced by the change.

Employees are incentivized to submit Kaizen suggestions, with recognition awarded to people who implement the most impactful improvements. Beyond the recognition, successful Kaizens are celebrated on billboards in employee meeting rooms.

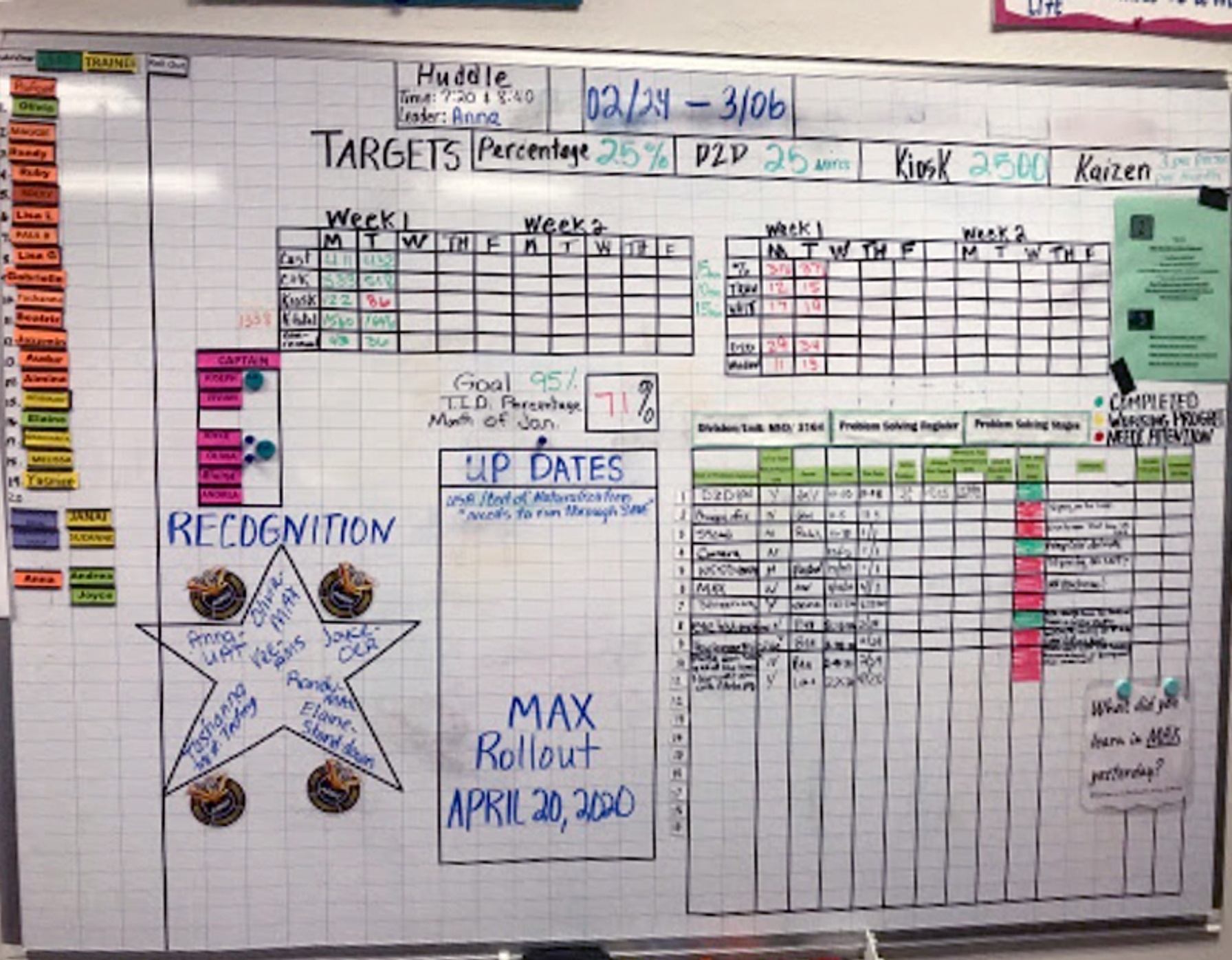

Huddle boards are another staple of MVD offices, providing daily visibility to progress on key metrics, like average wait times.

"Having those daily huddles and bringing everyone together to share problems is one of the most important things we do," Weiss said. "It gives everyone a place to surface problems in a safe and respectful way."

Among the other most important changes made at the MVD, Weiss said, was creating a standard of work that every office could follow. That includes standardizing the equipment and materials at every customer window and adjusting the flow in office lobbies, based on the specific layout of each building.

The overall goal is to create a better experience for every customer, complete with shorter wait times, forms that are easy to understand, and helpful employees who are well‐equipped to assist in every situation.

"We stepped back and looked at everything from the customer's perspective," Weiss said. "For example, we thought our website was easy to use, but looking at it from the customer's point of view, we realized it wasn't — so we changed it. By putting customers first, we're creating a better experience for residents across the state."

OUTSIDE THOUGHTS

"I was thoroughly impressed at the level of cultural change that the Arizona state agencies have undergone under the leadership of Governor (Doug) Ducey. The engagement from the front‐line staff at the Motor Vehicle Division was all‐in, and their metrics were improved beyond what anyone could have hoped for."

— Eric Siebeneck, Quality Improvement Advisor for Mayo Clinic

This story is the second part of a series on the Lean-based Arizona Management System (AMS). View the first story.

MoreSteam's Enterprise Process Improvement platform includes the tools, training, and software you need to transform your organization, large or small, into a problem-solving powerhouse. Our products are trusted by over half of the Fortune 500 and by other organizations and universities worldwide. When you partner with MoreSteam you gain a team dedicated to helping you succeed.