You cannot improve what you do not see.

But seeing a process clearly isn’t about drawing more boxes. It’s about learning to view work as a system and understand how it actually flows from start to finish. In today’s complex environment, teams often rush to fix isolated pieces of a process without first understanding how those pieces connect. We mistake activity for progress.

Sometimes the fastest way forward is to slow down long enough to understand the system. That means stepping back to see end-to-end flow, clarifying what creates value for the customer, and recognizing where work waits, loops, or breaks.

This Master Series is built on a simple idea: different problems require different perspectives. Choosing the right mapping technique starts with understanding what kind of problem you are trying to solve and what level of detail is needed to make a good decision.

Rather than teaching mapping tools in isolation, this program focuses on how process maps, value stream maps, value-added flow charts, and spaghetti diagrams work together to make work visible and guide improvement.

Early Bird Pricing: Register Now and Receive $75 Off*

Use coupon code MAPPING2026 to receive $75 off when you register for this 3-week master class.

*Early bird pricing discount available with coupon code only. Available now until 03/01/2026. Not available with any other promotion, discount, or coupon. Call for group pricing.

Mapping Master Series Training Sessions

March 11, 2026

Finding the Right Altitude & Defining the Problem

- How to move intentionally between different levels of system thinking

- Learning to recognize what level of detail is needed for the problem at hand

- Develop a high-level value stream map that reflects end-to-end flow

- Use a SIPOC to define clear process boundaries

March 18, 2026

Visualizing Flow, Handoffs, and Waste

- Create a process map with swimlanes to represent work flows across roles and handoffs.

- Apply value-added / non-value-added analysis to highlight improvement opportunities.

- Construct and interpret a spaghetti diagram to analyze physical or digital movement and identify unnecessary motion.

- Communicate process issues clearly using visual maps that support shared understanding across teams.

March 25, 2026

Using Maps to Prioritize Improvement

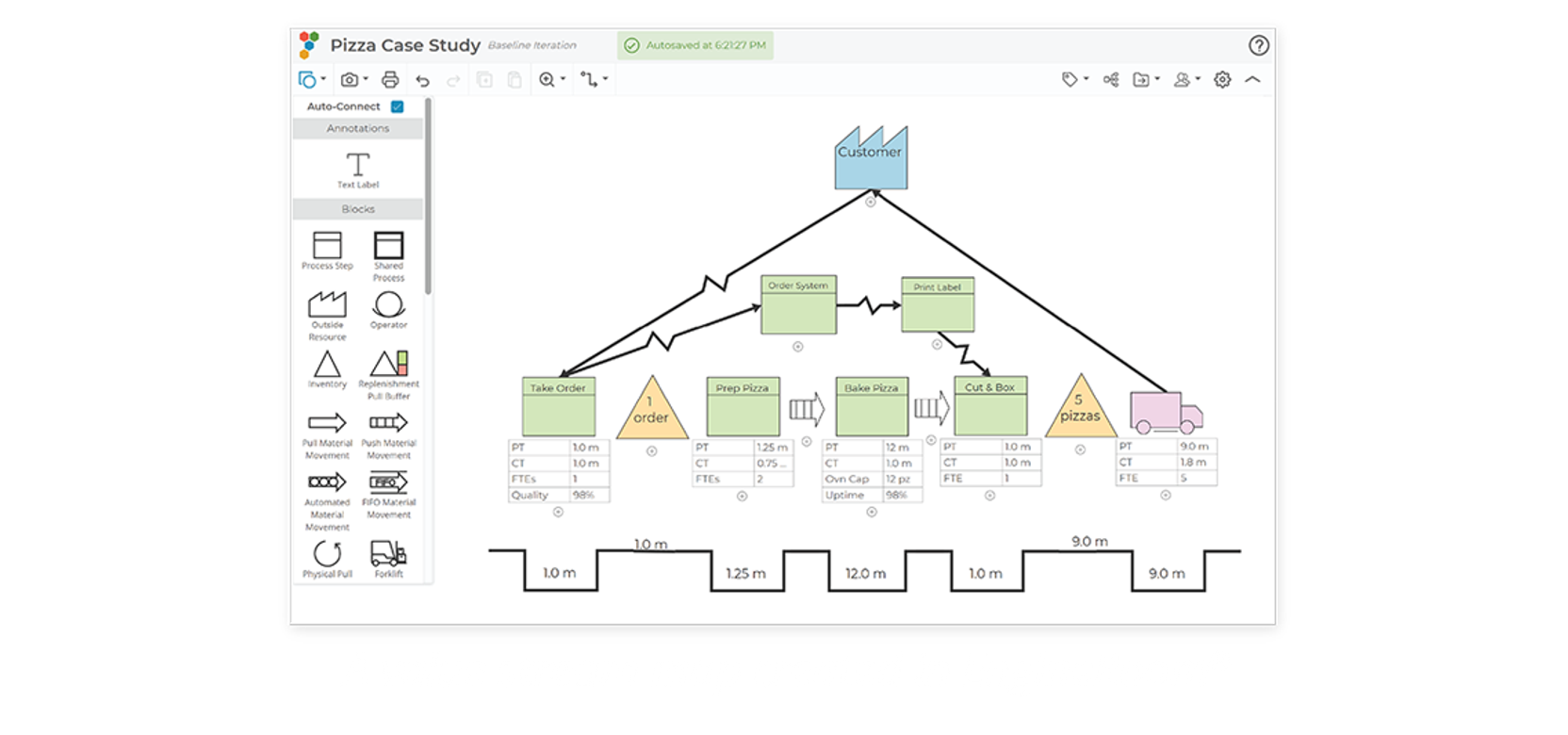

- Evaluate a value stream map that captures process flow, handoffs, delays, and queue time.

- Use process metrics like touch time, wait time, and takt time to interpret system performance.

- Differentiate between local improvements and changes that improve end-to-end system performance.

- Recognize when static mapping techniques are insufficient and when process modeling may be warranted.

Ready to Get Started?

What's Included:

- Three instructor-led sessions focused on seeing work as a system and using mapping to support improvement decisions

- Guided practice exercises that walk through framing, mapping, and interpreting real-world processes

- Hands-on application of core mapping techniques, including: SIPOC and high-level process framing Cross-functional (swimlane) process mapping Value-added and non-value-added analysis Spaghetti diagrams for physical and digital flow Current-state value stream mapping

- Examples and case scenarios that show how mapping reveals handoffs, delays, and constraints across different types of work

- A digital certificate of completion recognizing foundational capability in process mapping for continuous improvement

Learn from Industry Leaders

Our instructors are seasoned professionals with extensive backgrounds in their fields, combining academic expertise with real-world experience. Expect interactive sessions, hands-on application, and expert guidance tailored to your learning journey.

President • MoreSteam

Peg Pennington joined MoreSteam's executive team in 2018 and today leads all company operations as President. Previously, Peg was the Executive Director of the Center for Operational Excellence at The Ohio State University, where she helped shape the Master of Business Operational Excellence ('MBOE') program and strengthen standards for Lean Six Sigma certification. She serves on the board of directors for the Lean Enterprise Institute (LEI). A recognized voice in operational excellence, Peg speaks at over a dozen national conferences each year and leads product workshops.

Before joining MoreSteam, Peg was the Executive Director of the Center for Operational Excellence at The Ohio State University. Peg holds a bachelor’s degree in finance from Michigan State University and an MBA from the University of Dayton.