5-Why Analysis

The 5-Why analysis method is used to move past symptoms and understand the true root cause of a problem by asking "why" five times successively.

It is said that by performing this exercise, you can you delve into a problem deeply enough to understand the ultimate root cause. By the time you get to the 4th or 5th why, you will likely be looking squarely at management practices.

This methodology is closely related to the Cause & Effect (Fishbone) diagram, and can be used to complement the analysis necessary to complete a Cause & Effect diagram.

Here is a real world example from a kitchen range manufacturer:

Symptom: There is too much work-in-process inventory, yet we never seem to have the right parts.

Why?

Symptom: The enameling process is unpredictable, and the press room does not respond quickly enough.

Why?

Symptom: It takes them too long to make a changeover between parts, so the lot sizes are too big, and often have the wrong parts.

Why?

Symptom: Many of the stamping dies make several different parts, and must be reconfigured in the tool room between runs, which takes as long as eight hours.

Why?

Symptom: The original project management team had cost overruns on the building site work, so they skimped on the number of dies — they traded dedicated dies and small lot sizes for high work-in-process (which was not measured by their project budget).

Why?

Root Cause: Company management did not understand Lean manufacturing, and did not set appropriate project targets when the plant was launched. It is almost universally true that by the time you ask why five times, it is clear that the problem had its origins in management.

Historical Perspective

Although the 5-Why problem solving technique has been popularized by the Japanese, this common-sense concept has been around for quite some time:

Benjamin Franklin's 5-Why Analysis:

For want of a nail a shoe was lost,

for want of a shoe a horse was lost,

for want of a horse a rider was lost,

for want of a rider an army was lost,

for want of an army a battle was lost,

for want of a battle the war was lost,

for want of the war the kingdom was lost,

and all for the want of a little horseshoe nail.

The text above is a common extension of the original theme from Poor Richard's Almanac

Hybrid Tools

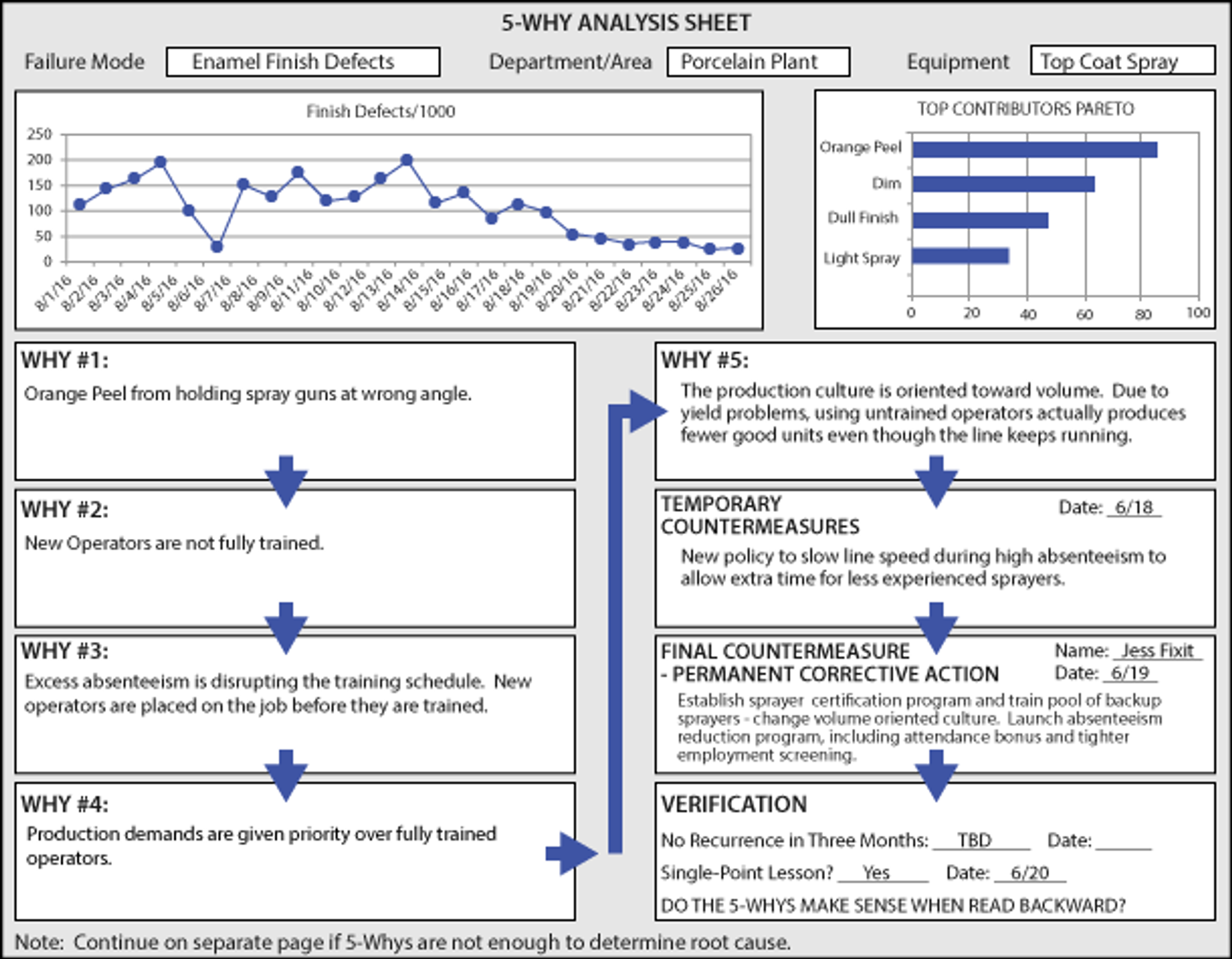

A Japanese transplant automobile manufacturer uses a hybrid form that includes a trend chart and pareto chart to guide the 5-Why thinking of its problem-solving teams. On one piece of paper, the form captures historical data, problem priorities, root cause analysis, corrective action, and verification. An example of the form is shown below with a hypothetical example from an appliance manufacturer.

Also, checkout the detailed tutorial below that shows how to use the 5-Why Analysis Tool in EngineRoom:

5-Why Analysis Tutorial

Summary

5-Why analysis is more than just an iterative process or a simple question asking activity. The purpose behind a 5-why analysis is to get the right people in the room discussing all of the possible root causes of a given defect in a process.

Many times teams will stop once a reason for a defect has been identified. These conclusions often do not get to the root cause. A disciplined 5-why approach will push teams to think outside the box and reach a root cause where the team can actually make a positive difference in the problem, instead of treating symptoms.