Closing the Gaps

May 24, 2016A Roadmap for Project Selection

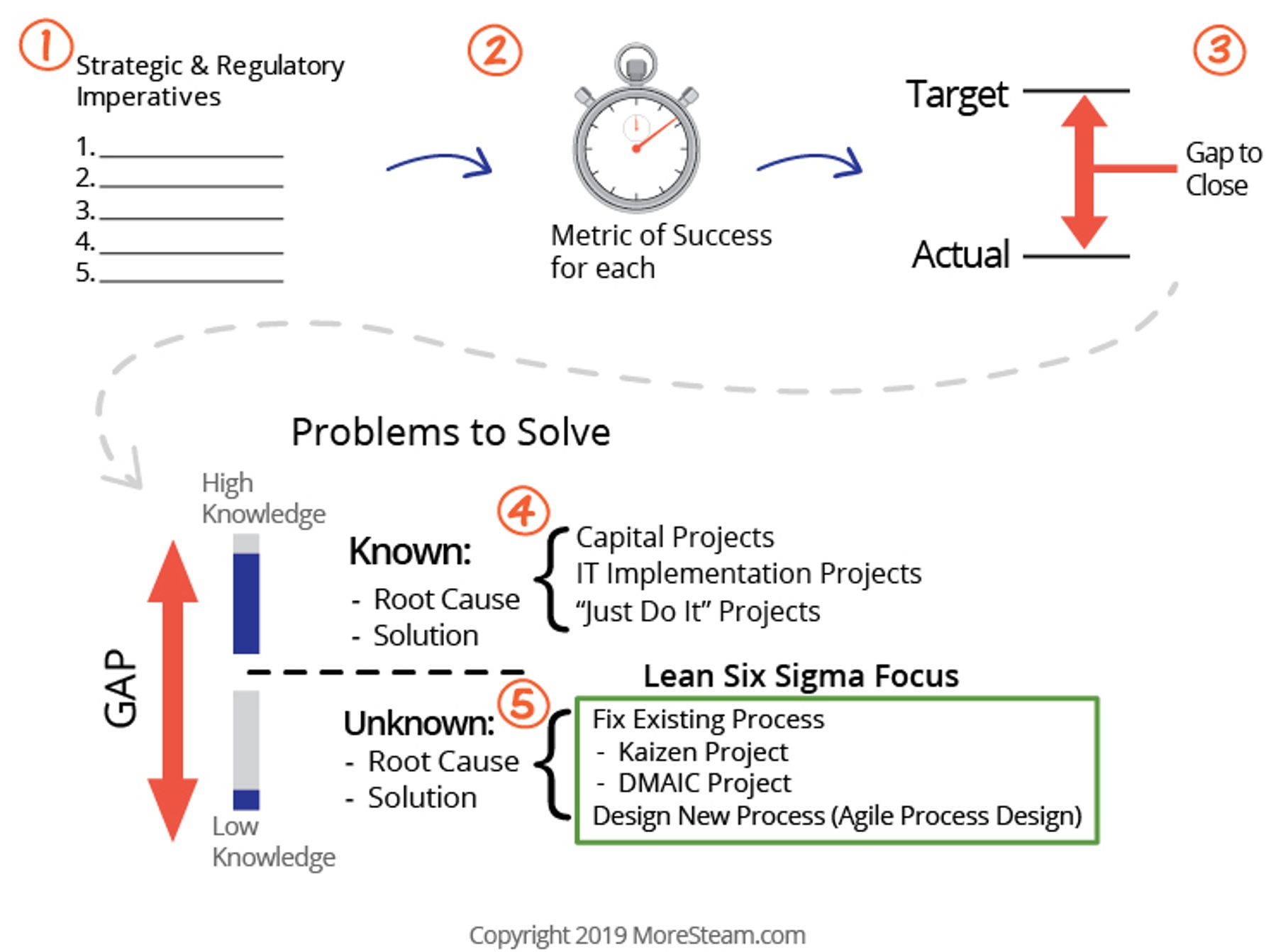

Over the last couple of weeks I've had the occasion to discuss the project selection process with a client, and I thought this diagram might be useful as a general roadmap.

The first step is to clarify the strategic and regulatory imperatives of the organization — the collection of activities that must be executed at a high level of capability for the organization to be successful.

Step two is to identify a way of measuring the performance of each imperative, as well as a target performance objective representing the required to be considered successful.

Once those key performance metrics and targets are established, actual performance can be compared to the target. Any shortfall in performance, or gap, must be closed by some activity. That's step three — which establishes the scope of work that must be performed.

Having quantified the gap to be closed, the next steps are to identify specific projects to help close the gap. These projects fall into two categories: those that address known root causes to implement known (or mostly known) solutions (step four), and those that address unknown root causes and unknown solutions (step five).

The known root cause and known solution arena representing step 4 is comprised of capital projects, IT implementation projects, and simple process improvement efforts (e.g. the room is cold, the window is open, so shut the window). These are projects where the tasks to implement can be identified at the front end.

The last step on the diagram, step 5, represents projects of discovery since the root cause and solution set are unknown. This is the realm of Lean Six Sigma: DMAIC projects fix more complex process problems, rapid improvement (Kaizen) events, and new product or process design efforts. These are projects where the specific tasks to implement are NOT known at the front end — only the questions to be answered are known.

In practice, project identification and selection is a lot more complicated than this simple diagram, but it's always best to start with a conceptual roadmap that is as simple as possible.