TRUSTED BY

About EngineRoom

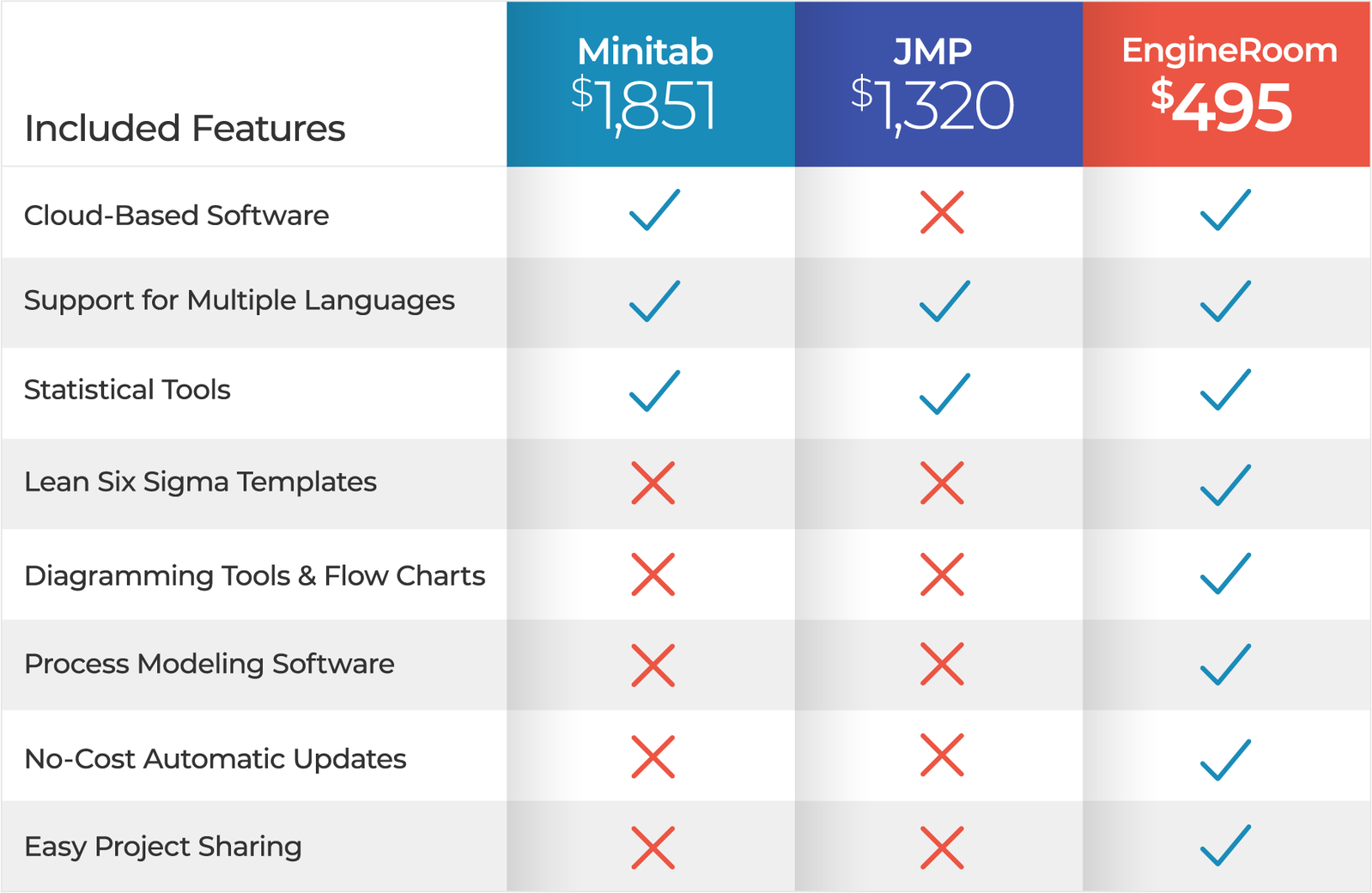

EngineRoom is an easy-to-use software platform designed to support process improvement initiatives in the medical manufacturing industry. Whether you're enhancing product quality, reducing production lead times, or ensuring regulatory compliance, EngineRoom provides the tools you need to analyze data, make informed decisions, and drive continuous improvement.

Our suite of statistical tools includes:

- Process Modeling

- Diagramming and Mapping

- Statistical Tools

- Project Documentation and Templates

Optimize Production and Reduce Lead Times

Efficient workflows are critical to delivering high-quality medical devices promptly. EngineRoom’s powerful suite of statistical tools enables teams to:

- Reduce Production Bottlenecks – Identify constraints in the manufacturing process and optimize operations for faster throughput.

- Improve Resource Utilization – Use data-driven insights to balance workloads, reducing downtime and enhancing productivity.

- Streamline Scheduling and Staffing – Leverage predictive analytics to align staffing levels with production demands.

Enhance Product Quality & Compliance

With EngineRoom, medical manufacturers can perform rigorous data analysis to improve product quality and generate the evidence needed to meet strict validation and compliance standards.

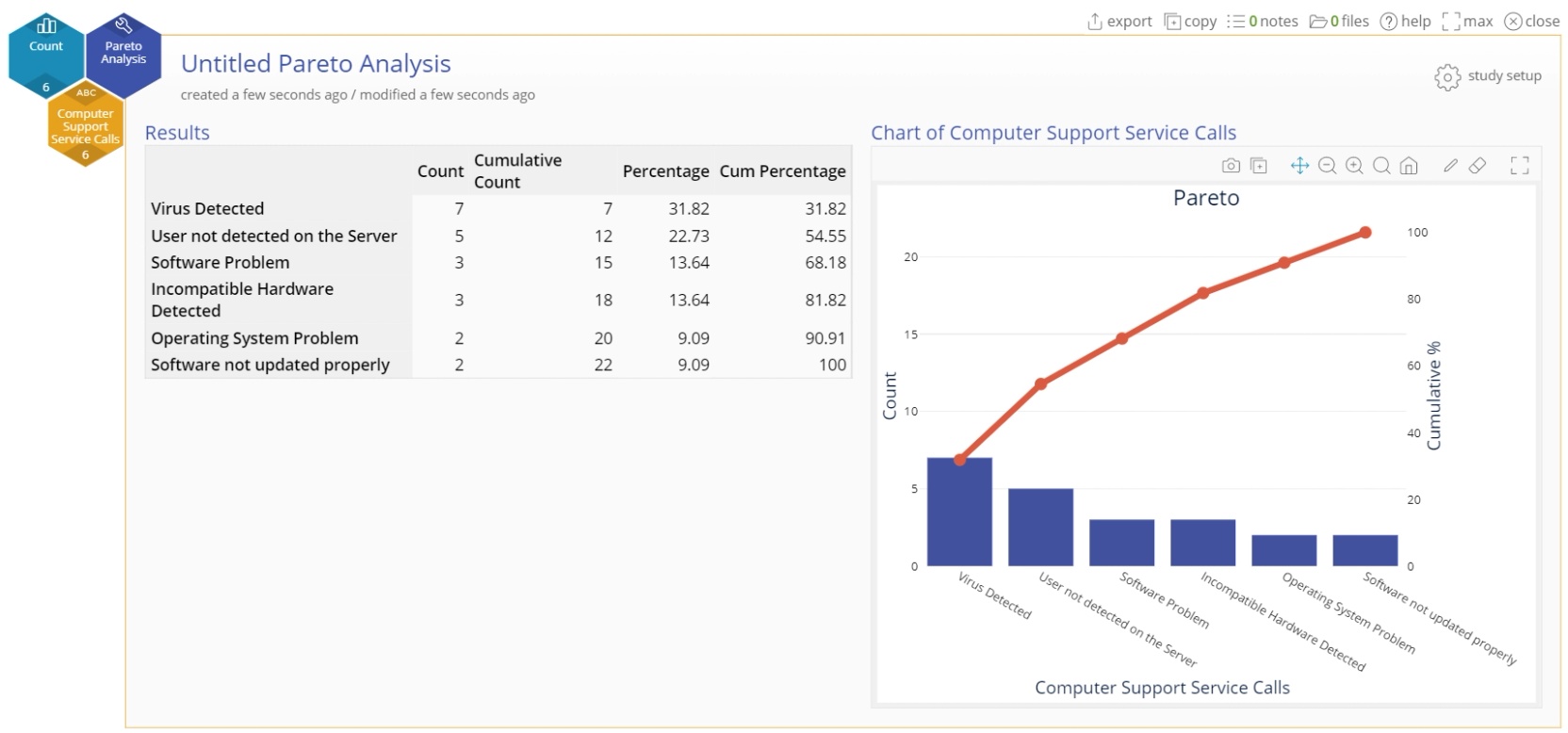

- Monitor and Improve Product Quality –Identify trends in production data to enhance product reliability and reduce defects.

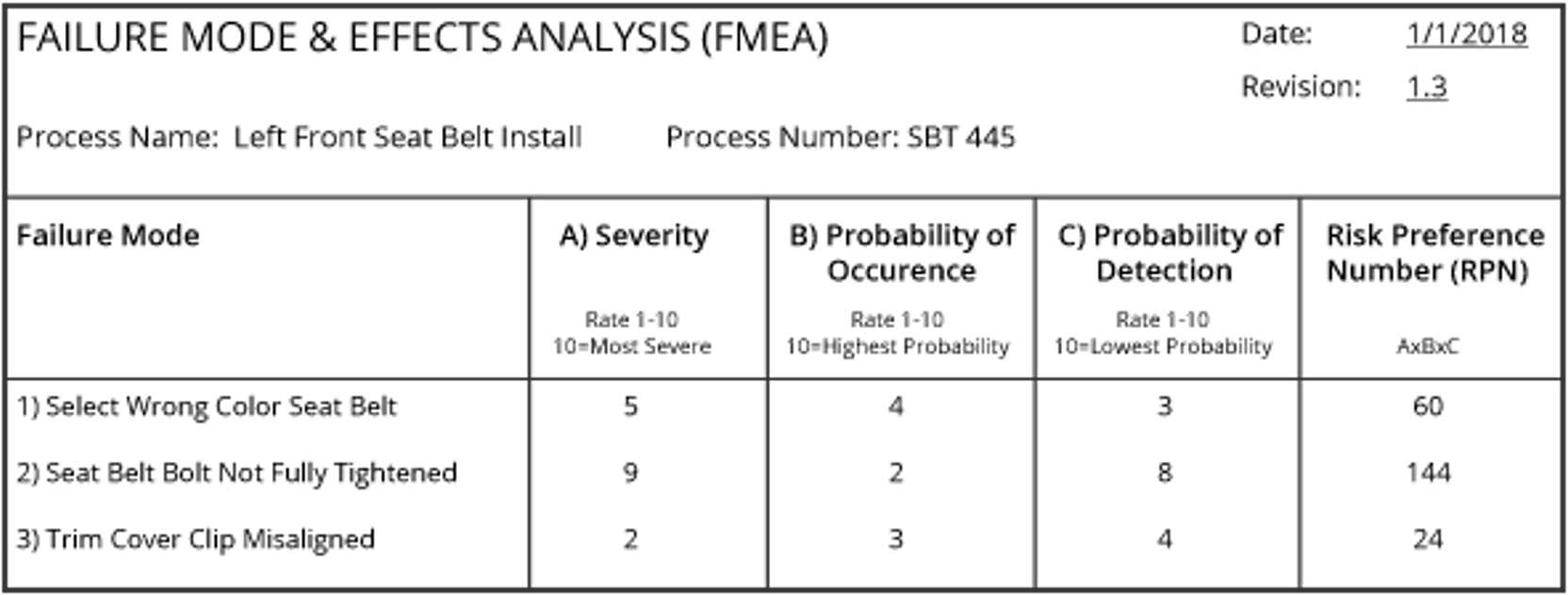

- Reduce and Prevent Manufacturing Errors – Use Failure Mode and Effects Analysis (FMEA) to proactively identify risks in production processes, detect potential failures before they occur, and prioritize corrective actions.

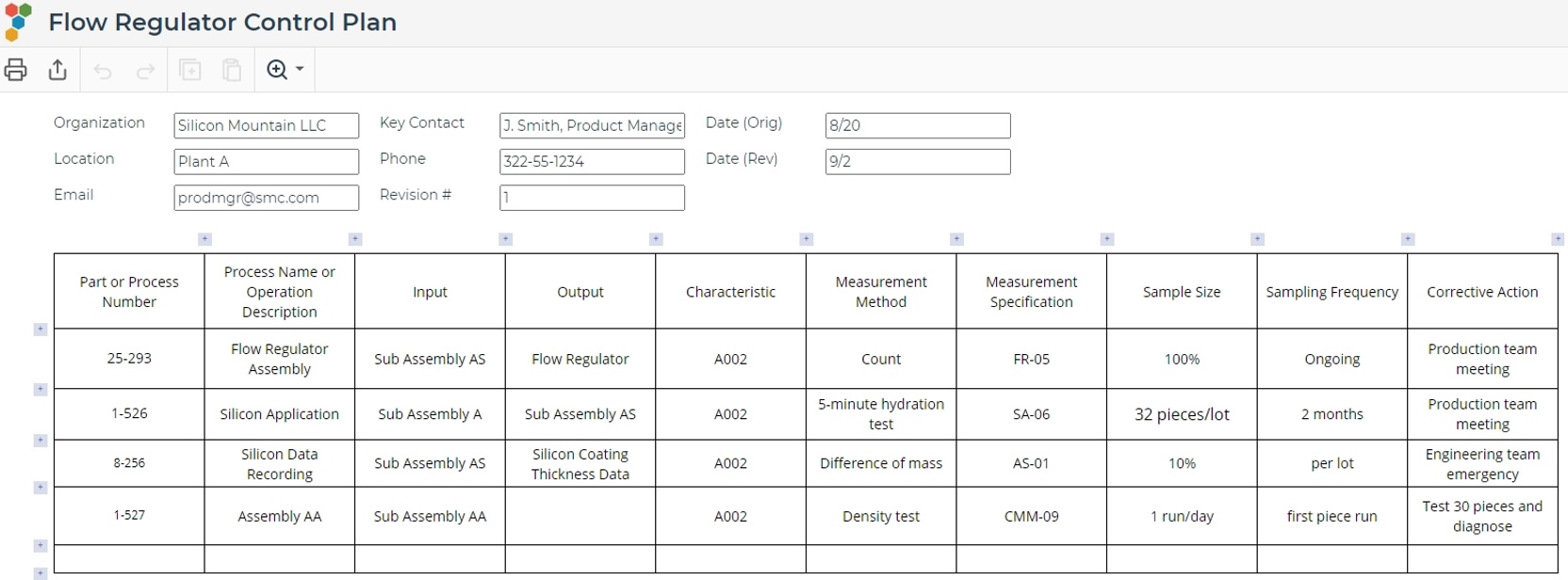

- Ensure Consistent Product Standards – Standardize processes across production lines for repeatable, compliant results.

In an industry where there's no room for trial and error, EngineRoom provides the analytical precision needed to make process improvements with confidence.

Regulatory Compliance & Data Security

EngineRoom is built to support the unique demands of medical manufacturing—where even incremental process changes must comply with federal guidelines and pass strict validation requirements.

- Maintain Regulatory Compliance – Minimize risks with documentation tools that support regulatory requirements.

- Ensure Data Security– Protect sensitive information with robust security features to handle and safeguard proprietary data.

- Improve Documentation & Reporting – Maintain precise, traceable records for audits, process validation, and quality initiatives.

EngineRoom ensures every improvement is fully documented and aligned with federal compliance requirements.

Cost and Resource Optimization

EngineRoom empowers medical manufacturers to manage resources efficiently and cut costs without compromising product quality.

- Optimize Resource Allocation – Improve efficiency in equipment, personnel, and materials using real-time data insights.

- Reduce Waste & Operational Costs – Identify inefficiencies in workflows and material usage to drive cost savings.

- Minimize Rework – Analyze root causes of defects and process failures to reduce material waste and avoid expensive rework.

See Why Trusted Professionals are Choosing EngineRoom

EngineRoom Software is the trusted tool for data analysis and process improvement professionals looking to cut costs without compromising quality. With its intuitive design, robust functionality, and affordable pricing, users consistently highlight EngineRoom's ability to simplify complex calculations and deliver impactful results.

Real-World Applications of EngineRoom Software

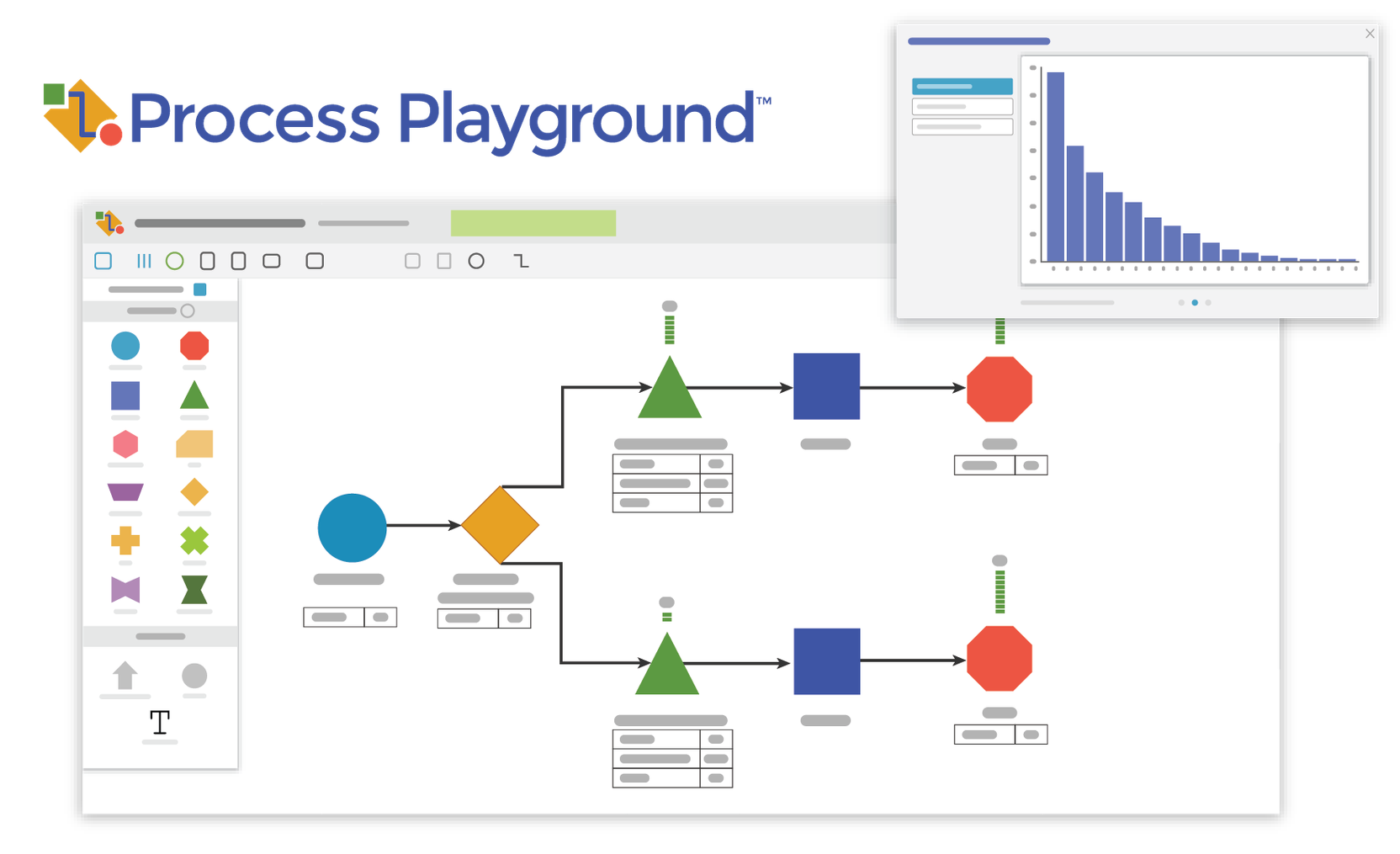

Medical manufacturers rely on EngineRoom’s intuitive Process Modeling tools to tackle complex production challenges, improve workflow efficiency, and drive measurable gains. EngineRoom empowers teams to build digital twins of their operations, test solutions virtually, and optimize processes before implementation.

Process Modeling Fuels Operational Excellence in High-Stakes Industry

Challenge: Medtronic faced underperformance on a high-demand production line for vessel-seal dissectors, with growing production pressures placing a premium on increasing output without sacrificing quality. The team was chartered to improve operating efficiencies and meet demand in a tightly regulated environment.

Solution: The team leveraged EngineRoom’s Process Playground to build a digital twin of their process. This simulation allowed them to test multiple process designs and predict outcomes—without disrupting production or investing additional capital.

Result: Medtronic increased operator and machine utilization to 98% and improved production output by 11.6%, all without additional capital investment.

Why It Matters: For medical manufacturers like Medtronic, this means validating changes before implementation—reducing risk, avoiding revalidation delays, and ensuring regulatory confidence. With EngineRoom's powerful process modeling tools, teams can reveal hidden inefficiencies, accelerate improvement, and boost output—without costly trial and error.

Read the case study! See how Process Playground can elevate your process improvement strategy.