TRUSTED BY

About EngineRoom

EngineRoom is an easy-to-use software platform designed to support process improvement initiatives and challenges of precision instrument manufacturing. From enhancing calibration accuracy to improving production quality and maintaining compliance, EngineRoom provides the tools you need to drive precision, reliability, and efficiency.

Our suite of statistical tools include:

- Project Documentation and Templates

- Process Modeling

- Diagramming and Mapping

- Statistical Tools

Enhanced Calibration Accuracy

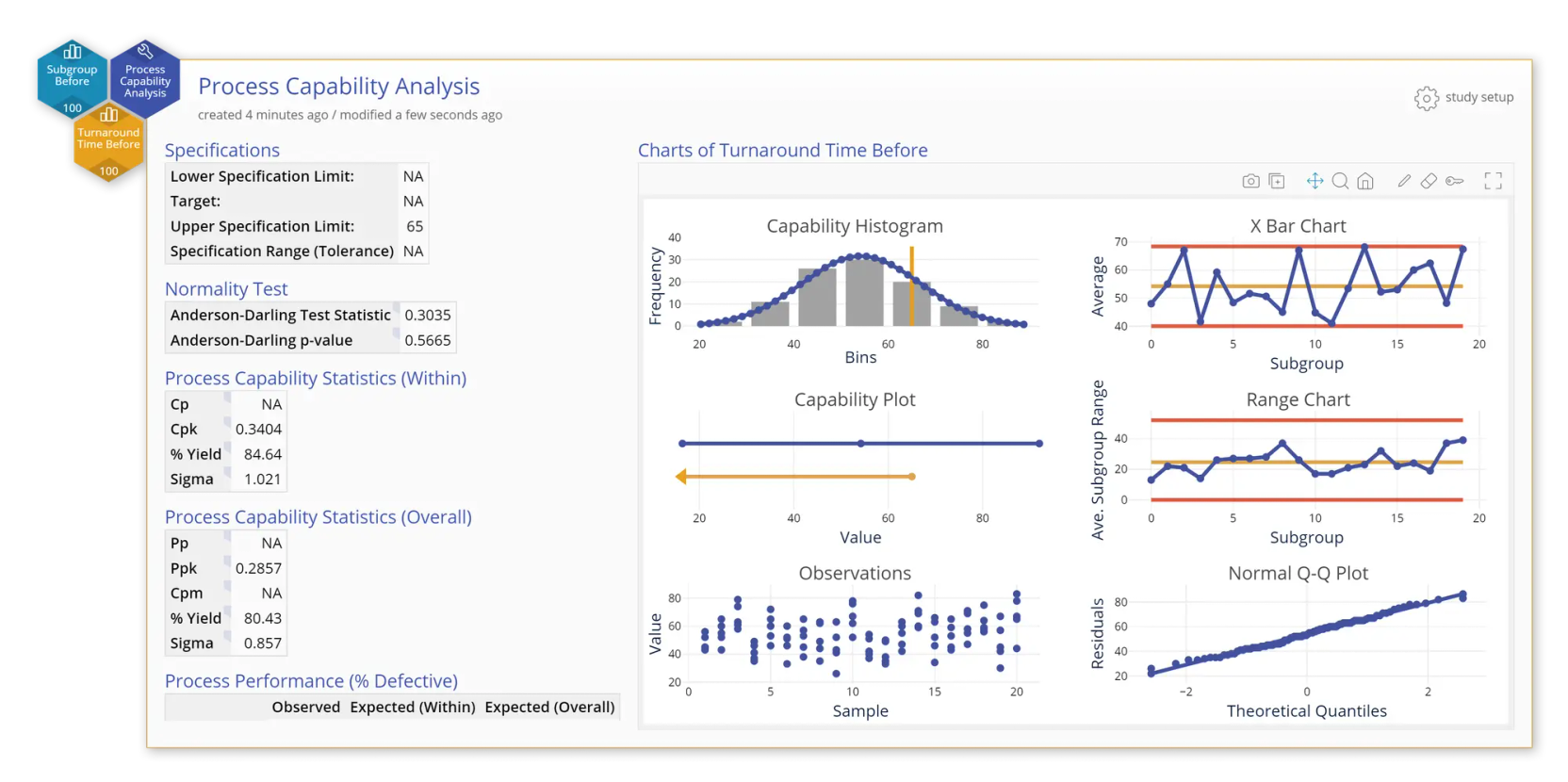

Precision instrument manufacturing relies on data-driven analysis to ensure measurement accuracy and reliability. EngineRoom’s powerful suite of statistical tools helps teams:

- Analyze Calibration Data for Inconsistencies – Identify and correct deviations in measurement systems before they impact production.

- Reduce Variability in Measurement Systems – Ensure process control by identifying sources of variation in test and measurement systems.

- Enhance Reliability – Improve repeatability in measurement processes to ensure consistent, high-precision performance across production cycles.

- Traceable Measurement Accuracy – Meet high-precision standards to comply with industry and regulatory requirements.

Improved Production Quality

EngineRoom enables manufacturers to refine production processes and maintain high-quality standards.

- Detect and Prevent Defects – Use data to identify defect patterns in production processes and implement proactive corrective actions.

- Implement Quality Control Measures – Leverage SPC tools to track and optimize process stability.

- Product Durability and Precision – Maintain consistency across batches through statistical analysis and modeling.

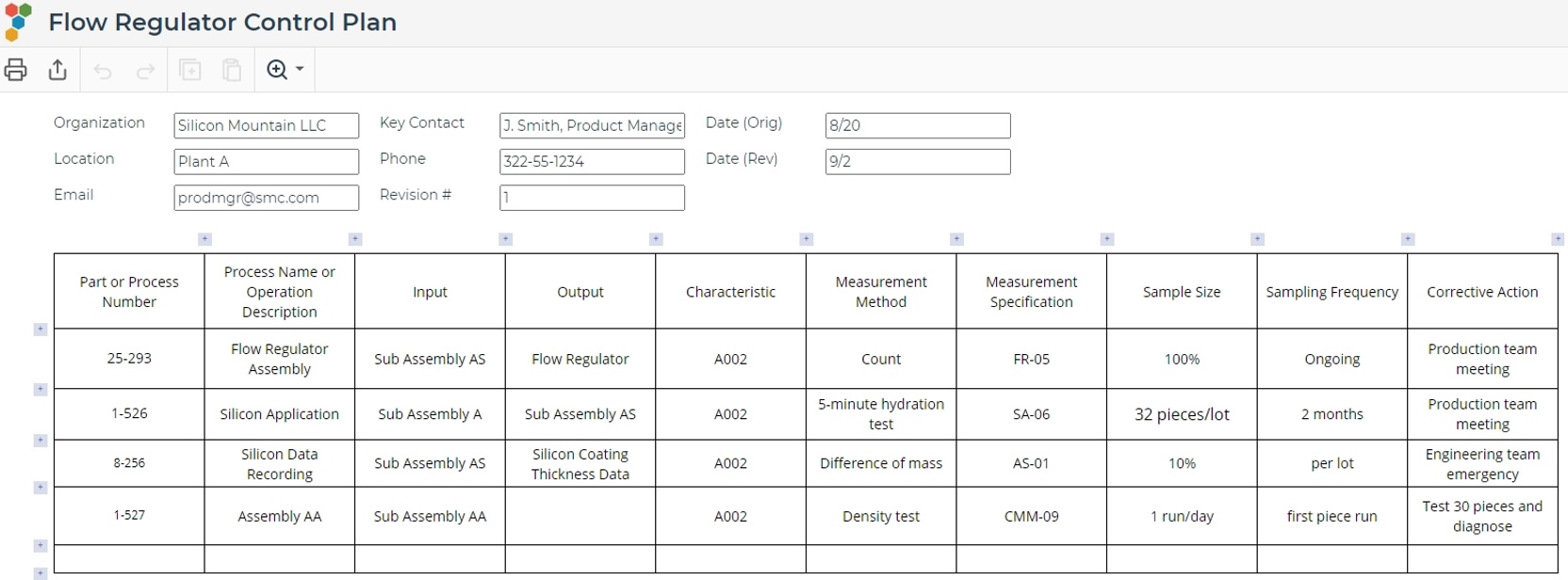

Compliance & Documentation

EngineRoom simplifies compliance tracking and ensures manufacturers stay audit-ready at all times:

- Compliance with Industry Regulations – Minimize risks with documentation tools that support regulatory requirements.

- Streamline Documentation & Reporting – Maintain precise, traceable records for audits, process validation, and quality control.

- Process Transparency – Digitally document workflows to ensure consistency and standardization.

- Audit-Ready Processes – Reduce compliance bottlenecks with structured reporting and proactive process monitoring.

Accelerated Process Development

From R&D to full-scale production, EngineRoom’s data analysis tools help manufacturers scale processes efficiently:

- Optimize New Product Testing & Validation – Use DOE tools to refine manufacturing parameters.

- Improve Prototype Testing – Identify key performance factors before full-scale implementation.

- Scale-Up Production – Leverage predictive modeling to ensure smooth transitions from small-batch to full production.

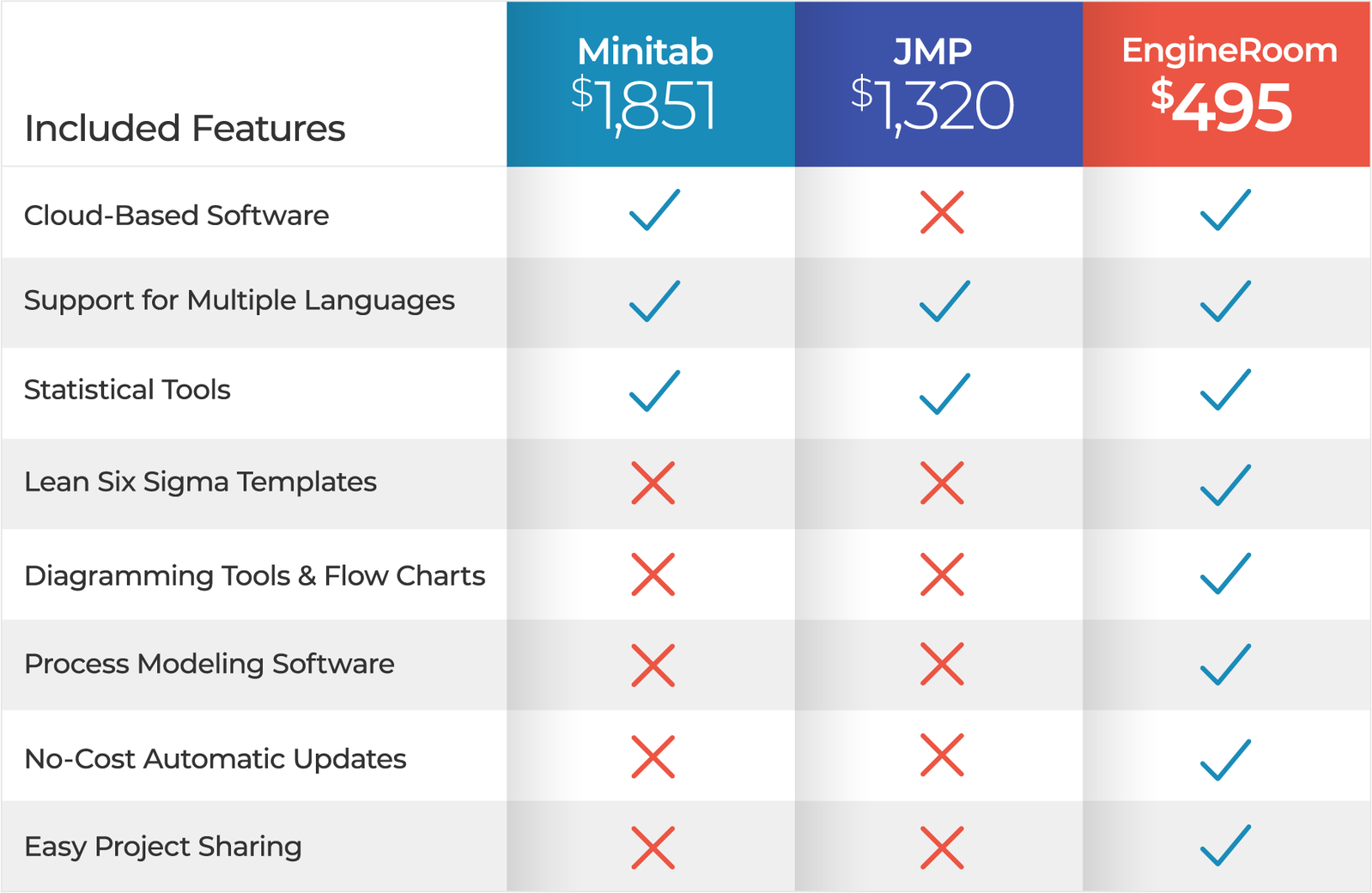

See Why Trusted Professionals are Choosing EngineRoom

EngineRoom Software is the trusted tool for data analysis and process improvement professionals looking to cut costs without compromising quality. With its intuitive design, robust functionality, and affordable pricing, users consistently highlight EngineRoom's ability to simplify complex calculations and deliver impactful results.

Real-World Applications of EngineRoom Software

Professionals are using EngineRoom’s intuitive DOE tools to tackle complex challenges, optimize processes, and achieve impactful, measurable outcomes. Here is an example of how DOE is making a difference:

Manufacturing: Reducing Defects, Improving Quality

Challenge: A manufacturer of electronic components was experiencing inconsistent product quality due to unknown process variations.

Solution: Using EngineRoom’s full factorial design of experiments, the team tested combinations of factors like soldering temperature, conveyor speed, and material properties.

Result: They identified the key drivers of defects and implemented changes that reduced errors by 30%, saving thousands in rework costs.

Why It Matters: DOE enables manufacturers to find answers faster, optimize processes, and maintain high-quality standards in competitive markets.