TRUSTED BY

About EngineRoom

EngineRoom is an easy-to-use software platform designed to support process improvement initiatives in chemical manufacturing. Whether you're optimizing production workflows, enhancing batch consistency, or reducing waste, EngineRoom provides the tools you need to analyze data, make informed decisions, and drive continuous improvement in your manufacturing operations.

Our suite of statistical tools include:

- Project Documentation and Templates

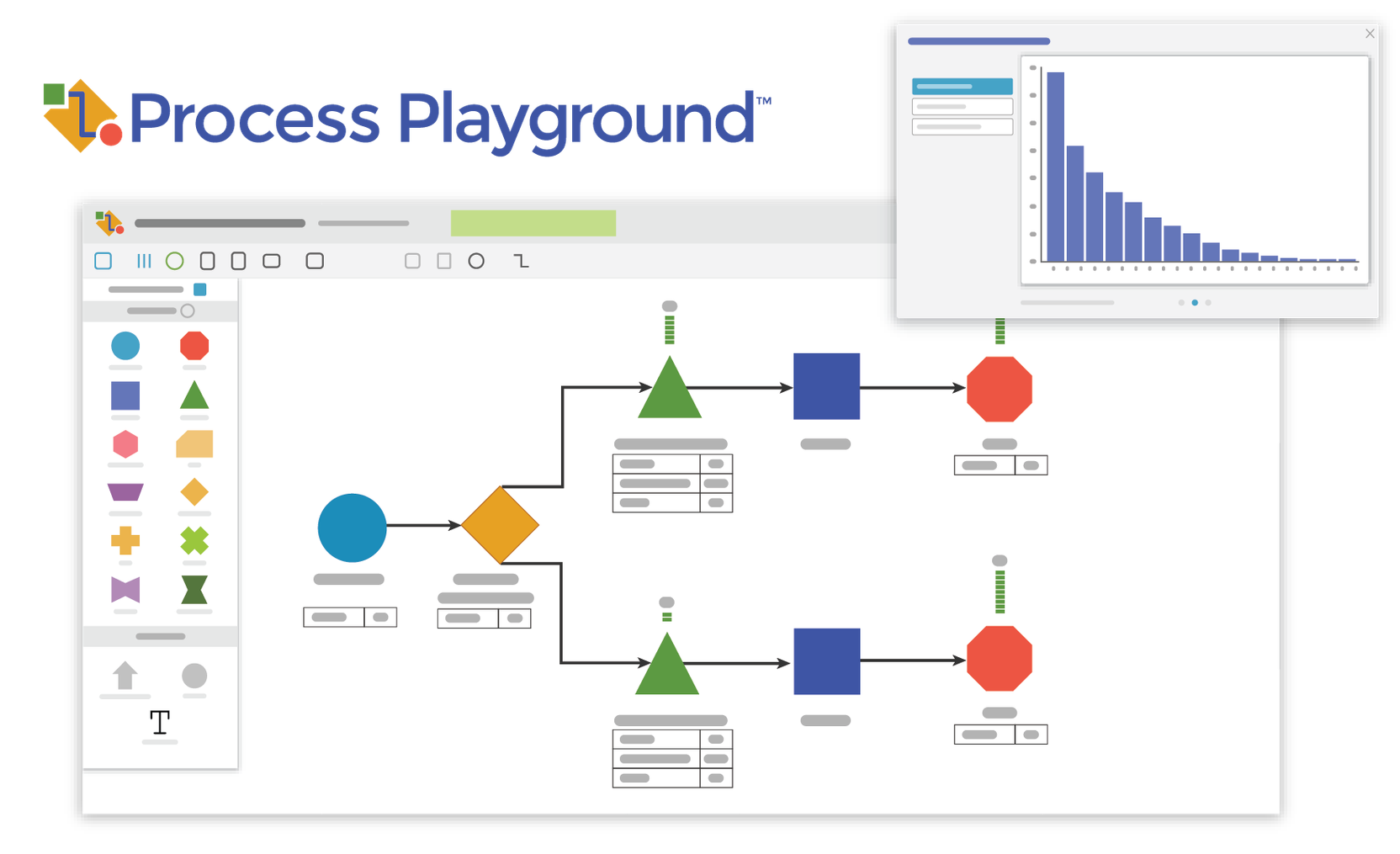

- Process Modeling

- Diagramming and Mapping

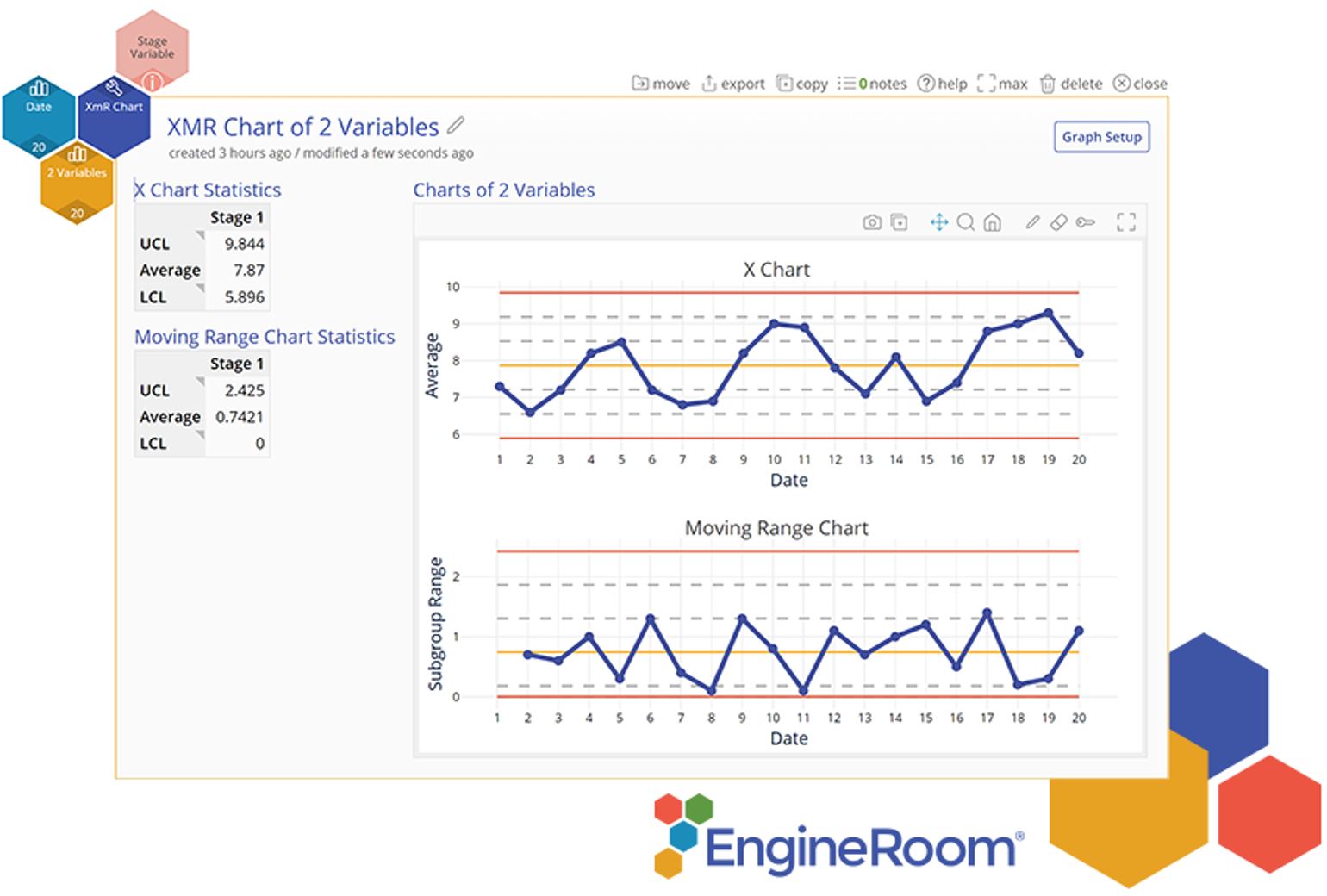

- Statistical Tools

Optimized Line Production

Chemical manufacturers rely on precise data analysis to maximize efficiency and maintain quality. EngineRoom’s powerful suite of statistical tools enables teams to:

- Increase Yield – Identify process bottlenecks and optimize production parameters to maximize output without increasing costs.

- Minimize Variability – Use advanced statistical analysis to detect sources of variation and maintain tighter process control.

- Enhance Efficiency – Leverage data-driven insights to streamline workflows, reduce waste, and improve resource utilization.

Enhanced Product Quality & Safety Compliance

With EngineRoom, manufacturing professionals can perform rigorous data analysis to monitor batch consistency and meet stringent safety standards. The platform’s advanced statistical capabilities ensure data-driven improvements that enhance quality and safety compliance.

- Ensure Consistent Batch Quality – Detect variations in raw materials and production conditions before defects occur.

- Meet Industry Standards – Maintain compliance with FDA, EPA, and OSHA regulations through process monitoring.

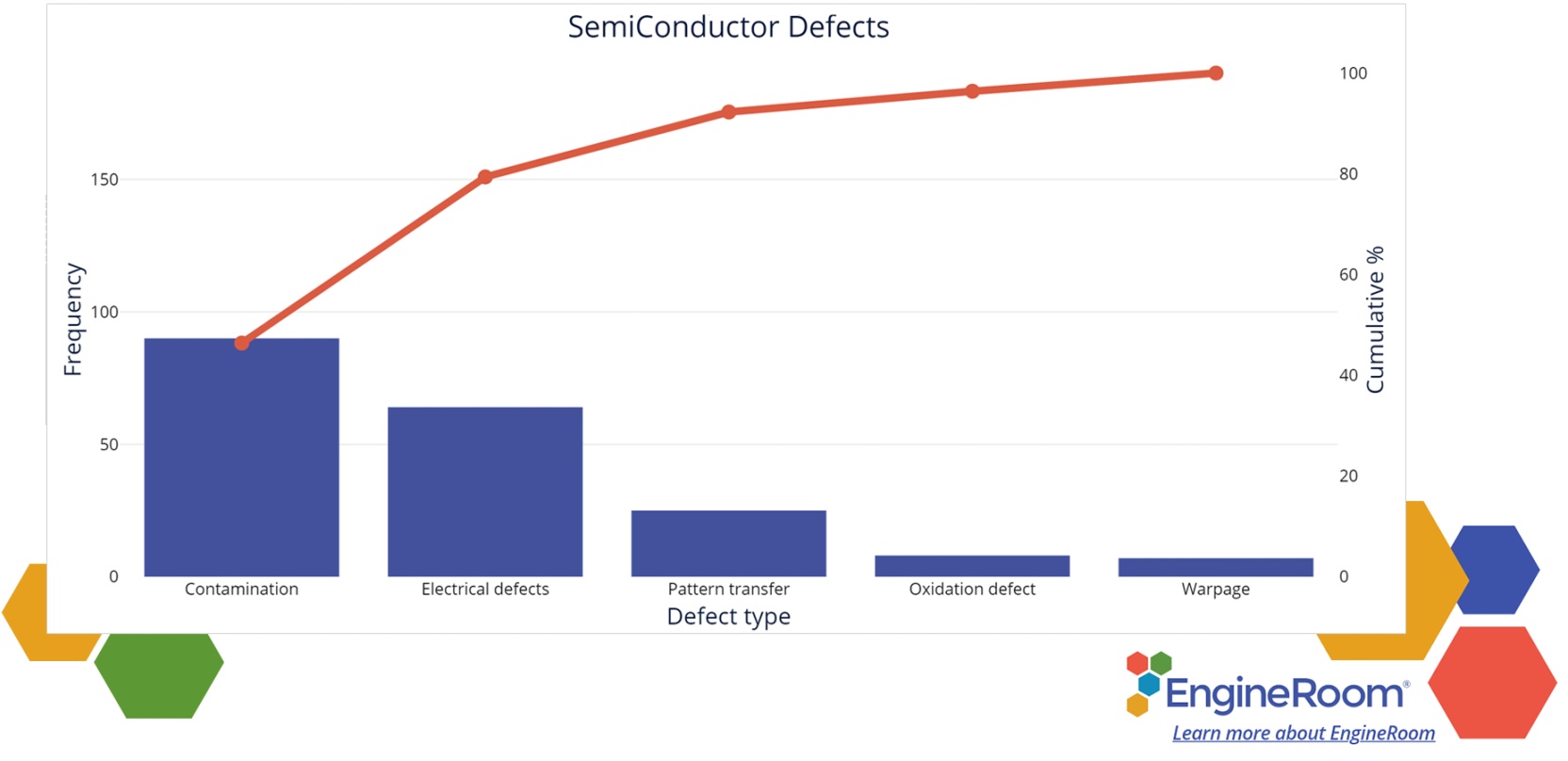

- Reduce Defects & Contamination Risks – Identify trends and inconsistencies to prevent quality issues before they escalate.

Cost & Waste Reduction

EngineRoom empowers manufacturers to track material usage, optimize resource allocation, and minimize production waste. These insights help reduce costs while driving more sustainable manufacturing practices.

- Minimize Material Waste – Identify process inefficiencies that lead to excessive raw material usage and unnecessary waste.

- Optimize Resource Allocation – Ensure the right amount of materials, energy, and labor are used to maximize productivity.

- Reduce Rework & Scrap – Pinpoint sources of defects early in the process to prevent costly rework and disposal.

Accelerated Process Development

Chemical manufacturers must continuously improve formulations, optimize reaction conditions, and scale production efficiently. EngineRoom’s Design of Experiments (DOE) and process modeling tools enable data-driven decision-making to drive innovation and process enhancements.

- Optimize Formulations – Use structured experimentation to refine chemical compositions, improve stability, and enhance product performance.

- Accelerate Process Scale-Up – Simulate lab-to-production transitions to ensure consistency and minimize costly trial-and-error.

- Enhance R&D Decision-Making – Leverage predictive analytics to test and validate process changes before full-scale implementation.

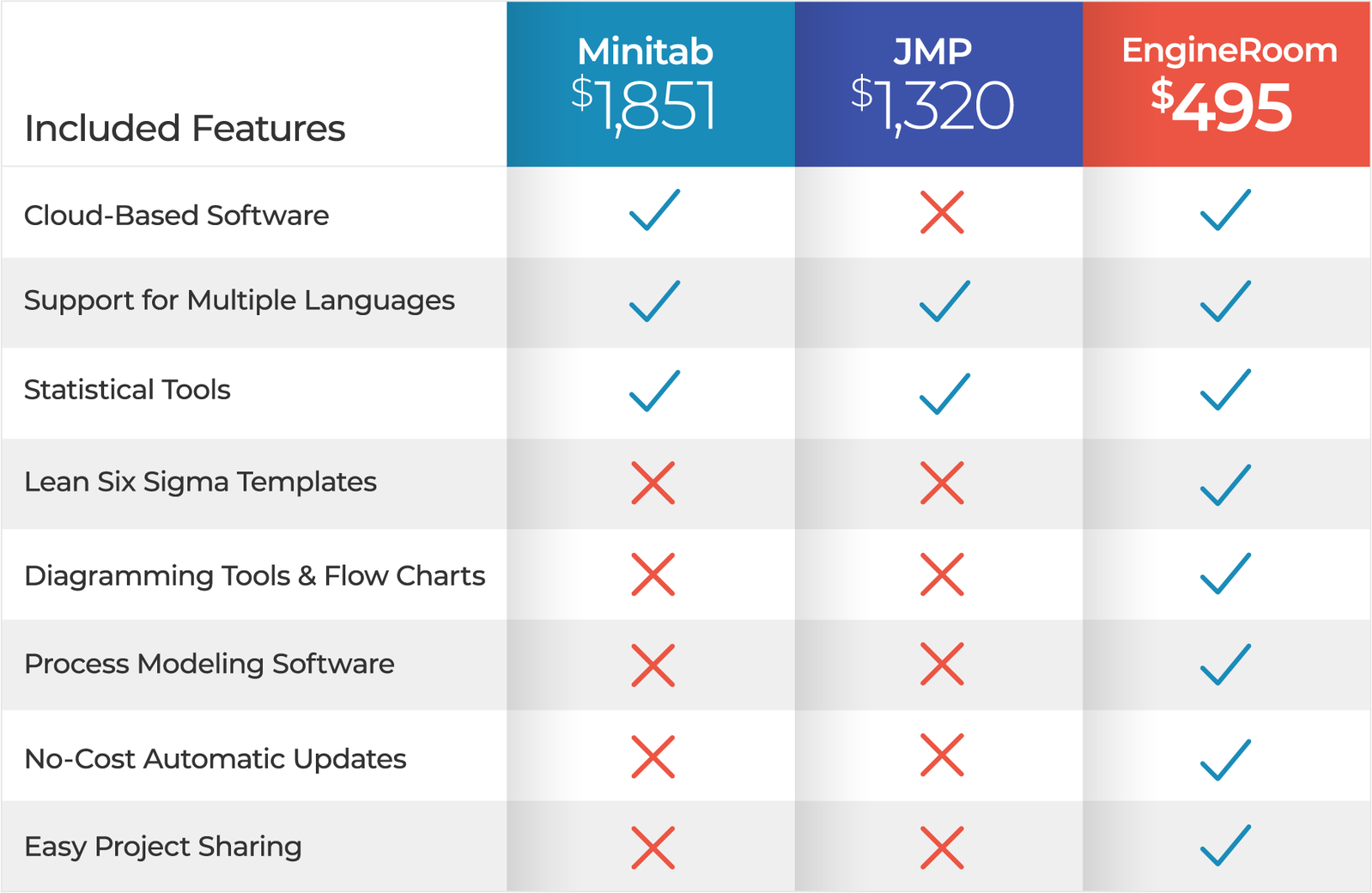

See Why Trusted Professionals are Choosing EngineRoom

EngineRoom Software is the trusted tool for data analysis and process improvement professionals looking to cut costs without compromising quality. With its intuitive design, robust functionality, and affordable pricing, users consistently highlight EngineRoom's ability to simplify complex calculations and deliver impactful results.

Real-World Applications of EngineRoom Software

Professionals are using EngineRoom’s intuitive DOE tools to tackle complex challenges, optimize processes, and achieve impactful, measurable outcomes. Here is an example of how DOE is making a difference:

Manufacturing: Reducing Defects, Improving Quality

Challenge: A manufacturer of electronic components was experiencing inconsistent product quality due to unknown process variations.

Solution: Using EngineRoom’s full factorial design of experiments, the team tested combinations of factors like soldering temperature, conveyor speed, and material properties.

Result: They identified the key drivers of defects and implemented changes that reduced errors by 30%, saving thousands in rework costs.

Why It Matters: DOE enables manufacturers to find answers faster, optimize processes, and maintain high-quality standards in competitive markets.