Inbox: A Workflow Simulation for Lean Office Training

From Theory to Practice: Embrace Lean with InBox®

Inspire Employees to Apply Lean in a Transactional Setting

SigmaBrew, a fictitious national chain of coffee shops, is experiencing rapid growth and cannot open up new store locations fast enough to keep up with its growth targets. It is up to the participants to work together, applying Lean concepts to transactional processes to get the retailer back on track. Unlike many manufacturing-oriented training simulations, InBox highlights the environment of the knowledge worker or the so-called “invisible factory.”

This immersive simulation takes place entirely in an email inbox, allowing participants to understand the value of improving day-to-day workflow in an office setting by identifying root causes and implementing necessary process improvements.

Time To Complete

6-8 hours

Participants

7-15 Participants

Key Concepts

Takt Time, Work-in-Progress (WIP), 8 Wastes, VSM, Error-Proofing, Line Balancing, Standard Work, Little's Law, Theory of Constraints (TOC), Visual Management, Basic Data Analysis

Experience a Lean Transformation in Action

InBox is MoreSteam's most popular Lean simulation. It condenses the essence of lean principles into a single, impactful day. In the sim, the power of Lean becomes clear as participants witness the elimination of waste and non-value-added activities, the streamlining of an invisible process, and the overall effectiveness of the process changes. More than just an exercise, InBox motivates participants to apply these concepts to their daily work.

Other benefits of running InBox include:

- Low-cost training solution for initiatives of all sizes

- Designed to replicate back-office processes realistically

- Participants experience the process, then apply Lean Six Sigma concepts

- Students can complete an entire project in less than a day

- Easy online access; no kits or set-up required

Showcase the Importance of a Lean Office

Just because you can't see the process doesn't mean it's not a candidate for improvement. Hidden waste is one of the most common forms of waste, especially when people aren't trained to look for it. Simulations like InBox provide an outlet to demonstrate the importance of Lean in a risk-free, practical, and effective way. It reaffirms the value of process improvement, and how it can apply to any setting, not just the ones on the manufacturing floor.

Most Lean Six Sigma simulations use role-play activities and a sequence of runs to practice improvement tools for tangible products like paper or assembled items. InBox is the first Lean simulation to employ an email-based workflow process. InBox effectively illustrates the use of Lean tools within an office environment, including: takt time, work-in-process metrics, error-proofing, line balancing, standardized work, value stream mapping, Little's Law, and Theory of Constraints (TOC).

The Project

This simulation works best with 7-15 participants. Players will work both independently and collaboratively throughout the simulation.

InBox uses the SigmaBrew case study, a large specialty coffee retailer struggling with quality and customer service issues in an increasingly competitive commercial market.

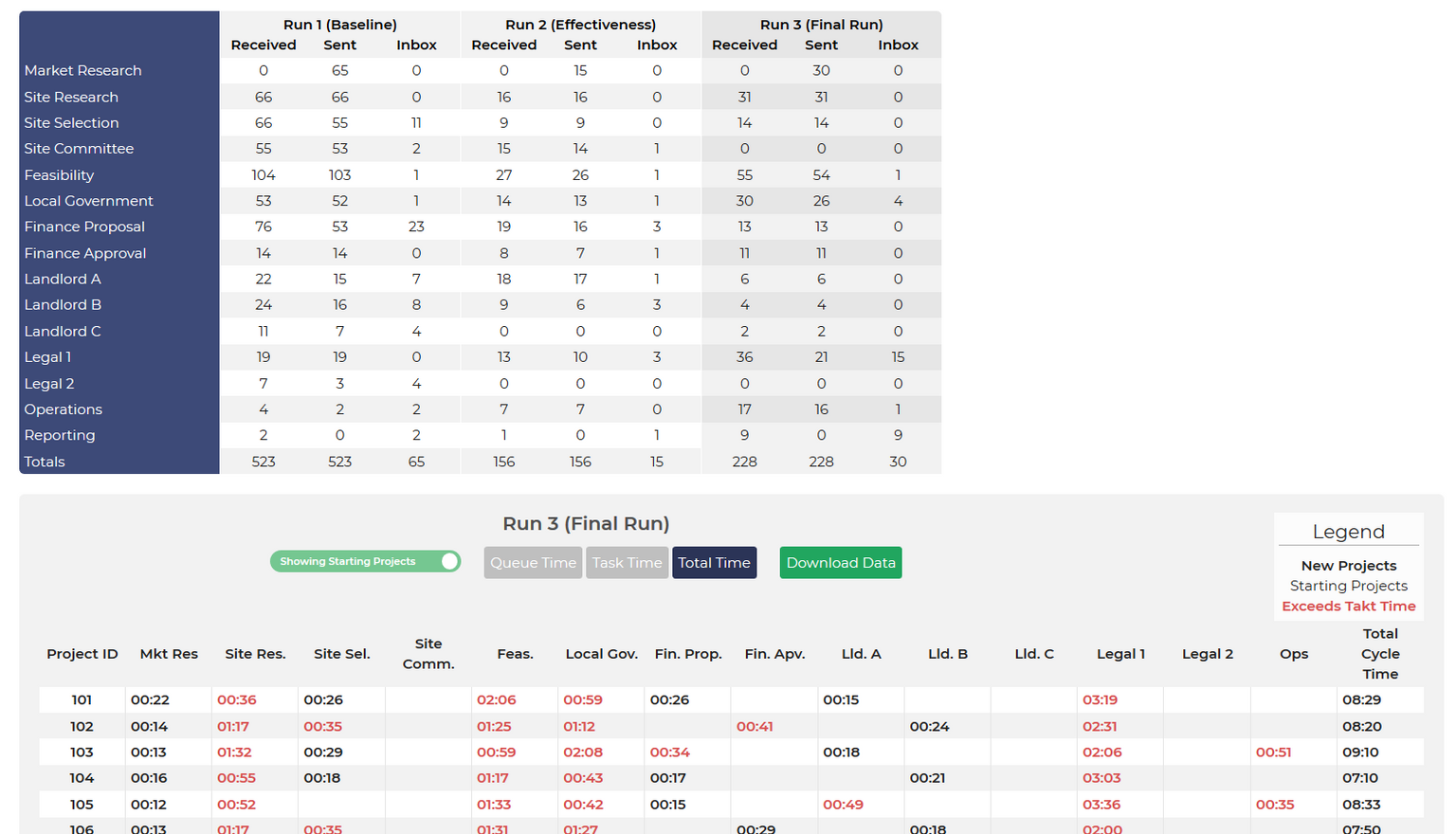

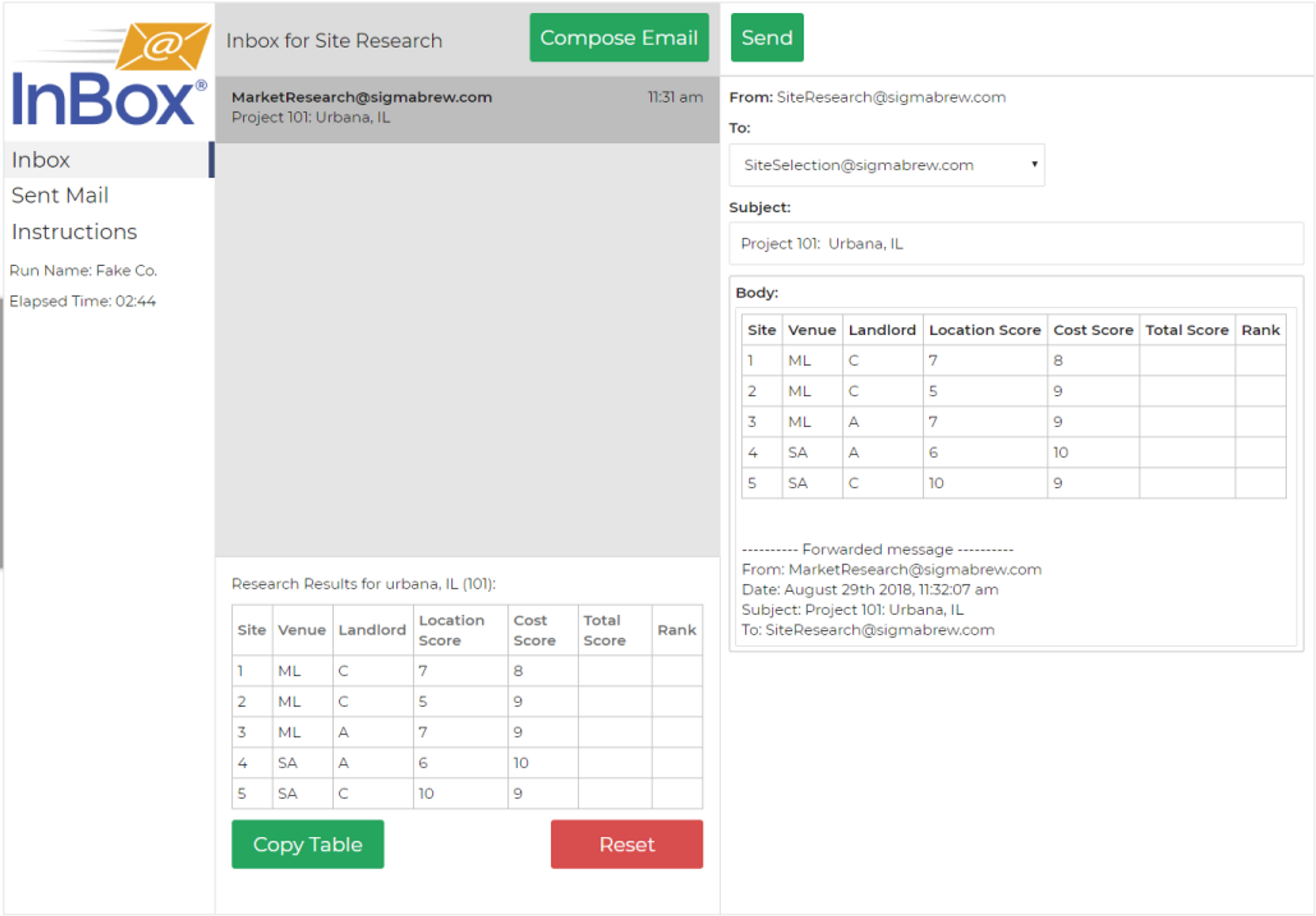

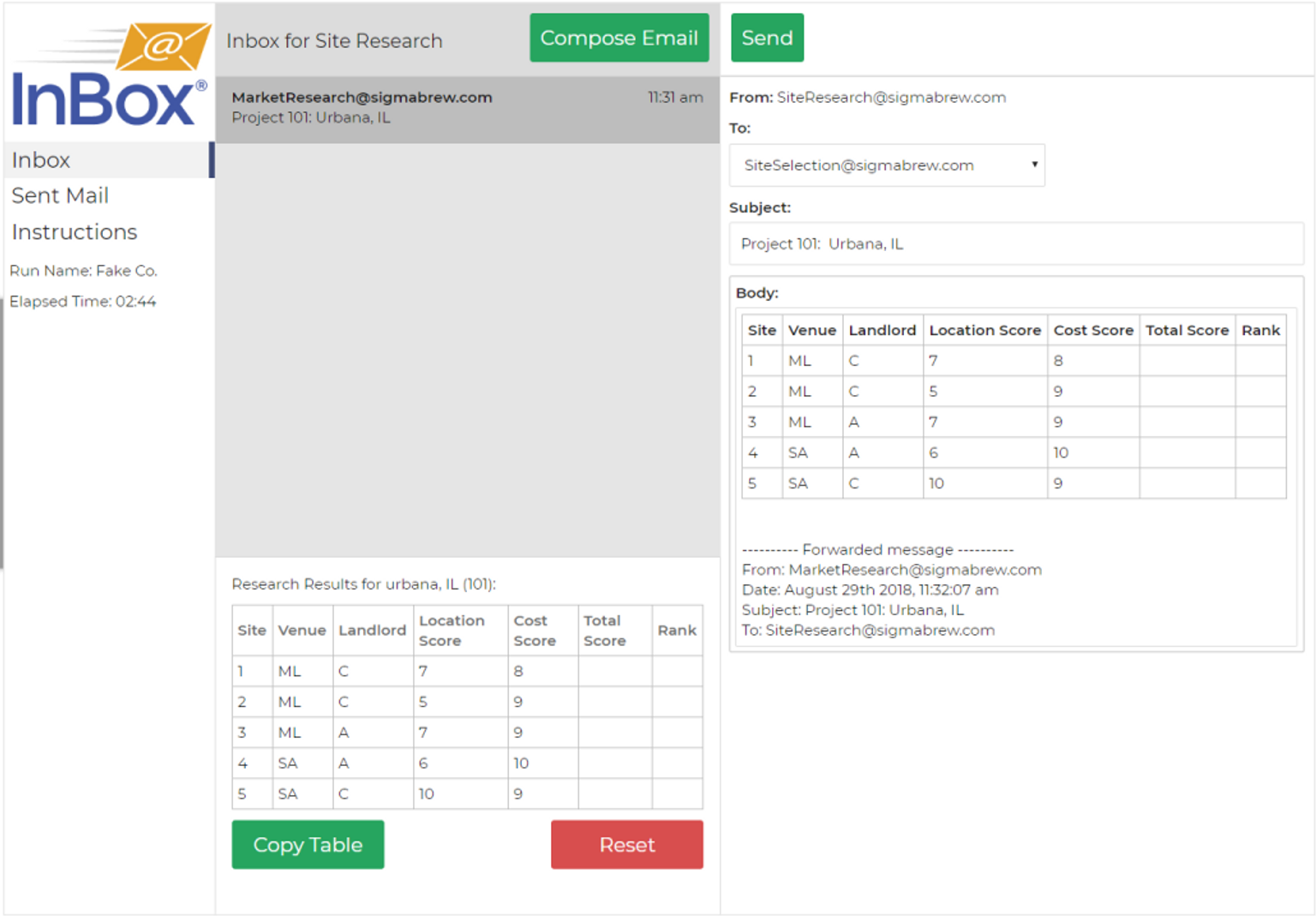

Each player is assigned a role, with their job instructions reflecting the kinds of emails they'll receive in their inbox. They perform their job (provided by their facilitator), then forward their work to the next player. After fifteen minutes, the game pauses, and participants discuss the current workflow, which they quickly learn is chaotic and inefficient.

All of the process activity, from the first step to the last, is documented and preserved. Each email is automatically time-stamped, making it easy to collect data on cycle time by work project. Players use this information to collaborate and create a value stream map, identify waste, and design improvements to the process. The team revises the work instructions based on the improvements they decide on and rerun the simulation to see if the suggested changes are effective.

Instructor Materials

Facilitators will receive an “Instructor's Version” of InBox, which has unique functionality from the players' version. It includes:

- Reset and reporting options

- Visibility into the simulation workflow, which allows you to keep everyone on track

Get Started

What's Included

- Facilitator account access

- Facilitation materials

- Simulation access and accounts for players

- MoreSteam customer service & support

What's Included

- Facilitator account access

- Facilitation materials

- Simulation access and accounts for players

- 1-on-1 facilitation support

- MoreSteam customer service & support

What's Included

- Simulation access

- Facilitation provided by MoreSteam

- Facilitation materials provided on request

- Simulation access and accounts for players

- MoreSteam customer service & support

Frequently Asked Questions

Still have questions? We're here to help.

614-602-8190

No Robots. Only humans.

support@moresteam.com

You'll still get a human here, too.